How paper is made

How paper is made

How Is Paper Made?

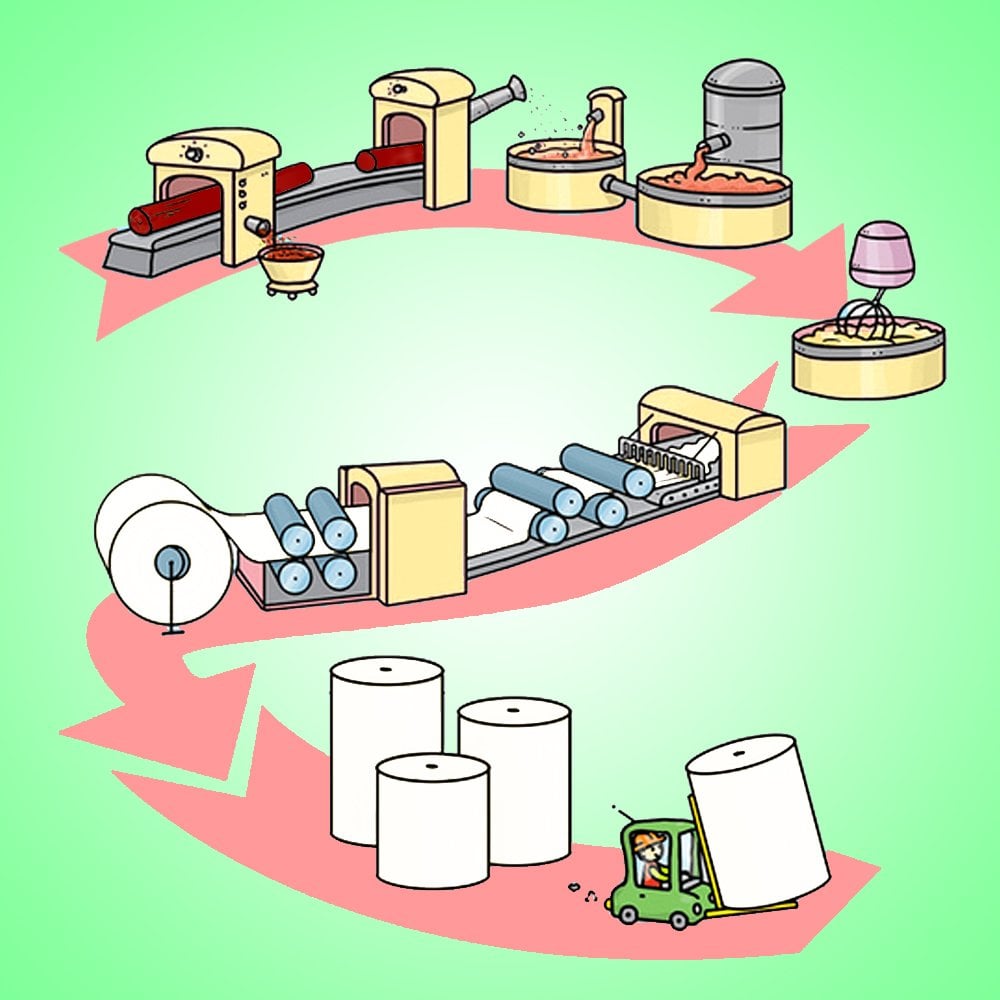

Paper is made from trees. The bark is peeled off the logs and the wood is diced into small chips. The chips are then cooked in a solution of acid to form a pulp. The pulp is then cleaned and bleached with water to remove the acid and any residual lignin. The pulp is then passed through a series of blades to flatten the fibers and eliminate inconsistencies. Finally, the paper is dried by making it gush through narrow spaces between rotating wires and belts.

Paper is one of mankind’s most revolutionary inventions. The invention of paper finally put an end to the cumbersome task of carving on wood or stone. In fact, the scope of information mankind could now limn was so enlarged that paper wasn’t merely used to catalogue the details of trade, but of daily events, to express feelings, wisdom, to write poems, to write stories we tell ourselves to transcend or escape the mundanity of life or stories that nature whispers to the ones who are keen to listen.

Photo Credit: Ginny / Flickr

No one is quite sure when the first sheet of paper was invented. What we do know is that it was invented some centuries ago in China, from where China’s extraordinary trading network ensured that it was eventually exported to other countries. However, how did the Chinese create it?

Recommended Video for you:

Trees

Surely, everyone is aware that paper is made from trees, but you’d be surprised to know that it is not made from their thin and soft leaves but rather their hard and rugged logs! A logical question, of course, is how does a rigid, inflexible log bear something as flexible and foldable as paper?

Photo Credit: Pixels

What the Chinese first did was peel the bark off the logs. The large cylinders of wood were then diced into chips as small as a few inches. The chips were dissolved and cooked in boiling water to form what is called a pulp. The cooking ensured that the wood was purged of its robust attributes. The pulp was then left to dry in a rectangular vessel. The solution, like cement, would gradually and completely dry to assume the shape of its container. What materialized was a thin, rectangular sheet of paper.

However, the paper obtained, due to the primitivity of the prevalent technology, was coarse and crude. What’s more, the paper would eventually turn yellow due to the presence of lignin, an organic polymer that comprises the intricate structures of plant tissues. As technology flourished, we figured that we could produce papers of a more refined quality. However, these papers would not only be smooth and velvety, but also wouldn’t be blemished yellow with age.

The Paper Mill

The way we make paper today is not very different from how the Chinese did it centuries ago. What differs is the modern technology, which makes the process exponentially more efficient. It also allowed us to meticulously refine or regularize the inconsistencies in the dried, flattened pulp. We also identified certain chemicals that, when dribbled into the cauldron, would alter the paper’s texture in accordance with our desires.

Today, the logs are first fed into a drum-shaped machine called a ‘debarker’ that, as the name suggests, separates the bark from the logs. The wood is then diced into single-inch chips and cooked in a solution of acid to separate the desirable plant fibers from the undesirable lignin, rendering the solution pulpy and fibrous. The pulp is then described as wood-free because it only contains plant fibers. This pulp is cleaned and bleached with water to remove the acid and ensure that no residual lignin survives. The treatment with water causes it to acquire the white color that is characteristic of paper.

Apart from the wood itself, water is the most important ingredient of the process. At least 100L of water is required to make 1kg of paper. However, engineers have devised clever ways to ensure that very little water is wasted. Almost 90% of the water is recycled by soaking or recirculating it on a mesh of pipes throughout the long process. In fact, a majority of the wood chips used are actually the waste products of sawmills! Even the chemicals used to bleach the pulp don’t include chlorine, but rather oxygen and peroxide, to ensure that no harm is inflicted on the environment.

Next, the pulp is passed through a series of adroitly placed blades to flatten the fibers, which were entangled like earphones in your pocket. Other than eradicating inconsistencies, this process also gives the fibers fibrillated ends, which facilitate fiber bonding with adjacent fibers, making the paper much stronger. Manufacturers also add calcium carbonate to the pulp to enhance its density and opaqueness, as well as starch or dyes to color it based on the buyer’s requirement, and optical brighteners to further improve the paper’s appearance.

Pulp. Photo Credit: Flicker /Paper Pulp

The pulp is now ready to dry. To eliminate the water, the pulp is fed into the paper machine, the heart of a paper mill. The paper machine is a conglomeration of different, smaller machines that simultaneously perform a variety of chores. Essentially, the pulp is dried by making it gush through narrow spaces between rotating wires and belts. The belts carry the water away, while the increased pressure and temperature ensure that a sheet of paper rolls out from the other end. To remove any residual moisture, the paper is subjected to infrared radiation.

The paper is then meticulously reviewed by experts who might send it for further refining to eliminate any inconsistencies that might have been spared in the previous processes. The rolls of paper produced can run up to 80km in length and 9m in width! A single roll can weigh as much as 120 tons! That is a lot of paper. Finally, the paper is divided into smaller lengths, which are loaded in cardboard boxes to be sold in the market.

A Paper Machine. Photo Credit: Pixabay

The pulp is also treated with different chemicals to create different kinds of paper, such as the craggy paper on which the content of a novel is printed, the smooth paper that forms its cover, tissue papers, and let’s not forget the most valued paper with which we buy every other paper: money! So, try not to take this most ubiquitous of materials for granted and appreciate the prudence and stringent labor that goes into making it.

Paper

Background

Formed from wood pulp or plant fiber, paper is chiefly used for written communication. The earliest paper was papyrus, made from reeds by the ancient Egyptians. Paper was made by the Chinese in the second century, probably by a Chinese court official named Cai Lun. His paper was made from such things as tree bark and old fish netting. Recognized almost immediately as a valuable secret, it was 500 years before the Japanese acquired knowledge of the method. Papermaking was known in the Islamic world from the end of the eighth century A.D.

Knowledge of papermaking eventually moved westward, and the first European paper mill was built at Jativa, in the province of Valencia, Spain, in about 1150. By the end of the 15th century, paper mills existed in Italy, France, Germany, and England, and by the end of the 16th century, paper was being made throughout Europe.

Paper, whether produced in the modern factory or by the most careful, delicate hand methods, is made up of connected fibers. The fibers can come from a number of sources including cloth rags, cellulose fibers from plants, and, most notably, trees. The use of cloth in the process has always produced high-quality paper. Today, a large proportion of cotton and linen fibers in the mix create many excellent papers for special uses, from wedding invitation paper stock to special paper for pen and ink drawings.

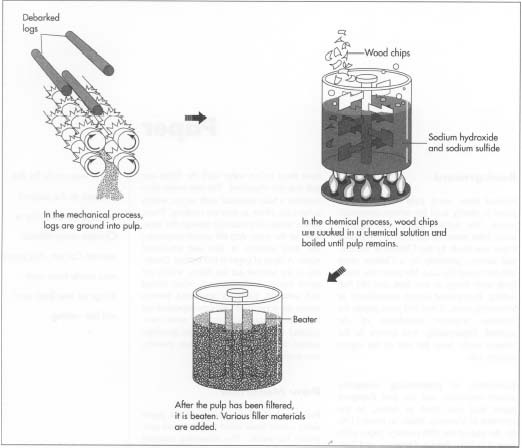

The method of making paper is essentially a simple one—mix up vegetable fibers, and cook them in hot water until the fibers are soft but not dissolved. The hot water also contains a base chemical such as lye, which softens the fibers as they are cooking. Then, pass a screen-like material through the mixture, let the water drip off and/or evaporate, and then squeeze or blot out additional water. A layer of paper is left behind. Essential to the process are the fibers, which are never totally destroyed, and, when mixed and softened, form an interlaced pattern within the paper itself. Modern papermaking methods, although significantly more complicated than the older ways, are developmental improvements rather than entirely new methods of making paper.

Raw Materials

Probably half of the fiber used for paper today comes from wood that has been purposely harvested. The remaining material comes from wood fiber from sawmills, recycled newspaper, some vegetable matter, and recycled cloth. Coniferous trees, such as spruce and fir, used to be preferred for papermaking because the cellulose fibers in the pulp of these species are longer, therefore making for stronger paper. These trees are called «softwood» by the paper industry. Deciduous trees (leafy trees such as poplar and elm) are called «hardwood.» Because of increasing demand for paper, and improvements in pulp processing technology, almost any species of tree can now be harvested for paper.

Some plants other than trees are suitable for paper-making. In areas without significant forests, bamboo has been used for paper pulp, as has straw and sugarcane. Flax,

Cotton and linen rags are used in fine-grade papers such as letterhead and resume paper, and for bank notes and security certificates. The rags are usually cuttings and waste from textile and garment mills. The rags must be cut and cleaned, boiled, and beaten before they can be used by the paper mill.

Other materials used in paper manufacture include bleaches and dyes, fillers such as chalk, clay, or titanium oxide, and sizings such as rosin, gum, and starch.

The Manufacturing

Process

Making pulp

Beating

Pulp to paper

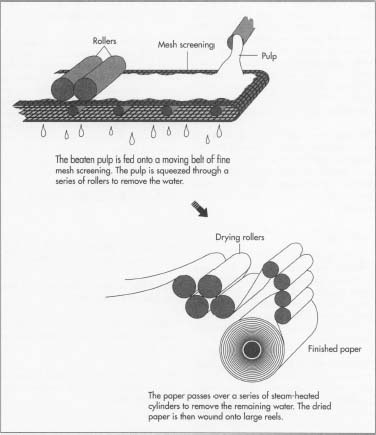

The paper then moves onto the press section of the machine, where it is pressed between rollers of wool felt. The paper then passes over a series of steam-heated cylinders to remove the remaining water. A large machine may have from 40 to 70 drying cylinders.

Finishing

The paper may be further finished by passing through a vat of sizing material. It may also receive a coating, which is either brushed on or rolled on. Coating adds chemicals or pigments to the paper’s surface, supplementing the sizings and fillers from earlier in the process. Fine clay is often used as a coating. The paper may next be supercalendered, that is, run through extremely smooth calendar rollers, for a final time. Then the paper is cut to the desired size.

Environmental Concerns

The number of trees and other vegetation cut down in order to make paper is enormous. Paper companies insist that they plant as many new trees as they cut down. Environmentalists contend that the new growth trees, so much younger and smaller than what was removed, cannot replace the value of older trees. Efforts to recycle used paper (especially newspapers) have been effective in at least partially mitigating the need for destruction of woodlands, and recycled paper is now an important ingredient in many types of paper production.

The chemicals used in paper manufacture, including dyes, inks, bleach, and sizing, can also be harmful to the environment when they are released into water supplies and nearby land after use. The industry has, sometimes with government prompting, cleared up a large amount of pollution, and federal requirements now demand pollutionfree paper production. The cost of such clean-up efforts is passed on to the consumer.

Where To Learn More

Books

Biermann, Christopher J. Essentials of Pulping & Papermaking. Academic Press, 1993.

Bell, Lilian A. Plant Fibers for Papermaking. Liliaceae Press, 1992.

Ferguson, Kelly, ed. New Trends and Developments in Papermaking. Miller Freeman, Inc., 1994.

Munsell, Joel. Chronology and Process of Papermaking, 1876-1990. Albert Saifer Publisher, 1992.

Periodicals

deGrassi, Jennifer. «Primitive Papermaking.» Schools Arts, February 1981, pp. 32-33.

Kleiner, Art. «Making Paper.» Co-Evolution Quarterly, Winter 1980, p. 138.

Lamb, Lynette. «Tree-Free Paper.» Utne Reader, March-April 1994, p. 40.

Saddington, Marrianne. «How to Make Homemade Paper.» Mother Earth News, December-January 1993, p. 30+.

Sessions, Larry. «Making Paper.» Family Explorer, October 1994.

Paper and papermaking

I f you weren’t glued to your computer screen right now, you might be reading this article on paper from a book; for about 2000 years until the appearance of the World Wide Web, virtually all written information was distributed in printed form. The idea of getting information from inked-up sheets of paper is starting to seem a little bit old-fashioned, but that doesn’t mean we’re going to ditch paper anytime soon. People have been predicting the arrival of the «paperless society» for decades and it still seems no nearer; if anything, we use more paper now than ever before—and not just for printing. Huge amounts of paper and card are still used for product packaging, in towels and diapers, and in a wide variety of building materials. It’s probably no exaggeration to say that paper is the world’s favorite material. Let’s take a closer look and what it is and how it’s made!

Photo: Even in the computer age, we still use vast quantities of paper. This photo could have been taken yesterday; in fact, it was shot in 1943 at the huge Southland Paper Mills near Lufkin, Texas, and shows newsprint (paper for printing newspapers) made from wood pulp using the Kraft process. Photo by John Vachon for the Office of War Information, courtesy of US Library of Congress.

Contents

What is paper?

Paper is a dried, compressed mat of plant fibers—nothing more, nothing less. It’s a bit like clothing you can write on. No, really! Clothes are made by weaving together yarns such as cotton and wool spun from natural fibers. Paper is more like the fabric we call felt, made without the weaving stage by pressing together cellulose fibers extracted from plants and trees so they knit and fuse to form a strong, solid, but still very flexible mat.

How is paper made?

Most paper pulp is made from trees (mainly fast-growing, evergreen conifers), though it can also be made from bamboo, cotton, hemp, jute, and a wide range of other plant materials. Smooth papers used for magazines or packaging often have materials such as china clay added so they print with a more colorful, glossy finish.

Photo: Paper can be made from lots of different materials. 1) Trees felled for papermaking. Although many different tree species can be used, hardwoods provide the bulk of the fibers in paper, while softwood fibers are used more for strength. 2) Stacks of hay waiting to be made into low-grade paper in Hebei Province, China. China and the United States are the world’s leading paper makers, each producing close to 80 million tons of paper per year. Photo by Simon Tsuo courtesy of US DOE/NREL (US Department of Energy/National Renewable Energy Laboratory).

Here’s the basic idea: you take a plant, bash it about to release the fibers, and mix it with water to get a soggy suspension of fibers called pulp (or stock). Then spread the pulp out on a wire mesh so the fibers knit and bond together, squeeze the water away, dry out your pulp, and what you’ve got is paper!

Paper is really easy to make by hand (try it for yourself) but people use so much of it that most is now made by giant machines. Whichever method is used, there are essentially two stages: getting the pulp ready and then forming it and drying it into finished sheets or rolls.

Chart: Recycled paper (green line) has now overtaken woodpulp (brown line) as the main source of raw materials. In Europe (EU plus Norway and Switzerland), about 72 percent of paper was recycled in 2019, compared to just 40 percent in 1991. Even so, very large amounts of wood are still consumed to make paper: roughly 154 million cubic meters of wood are used by the European paper industry each year (28 percent hardwood and 72 percent softwood), but only about 40 million cubic meters of that (less than a third) finds its way into papermills as usable pulp. Chart based on statistics from Key Statistics: European Pulp and Paper Industry 2019, Confederation of European Paper Industries (CEPI), 2020.

Papermaking by hand

Photo: Look really closely at almost any ordinary paper and you’ll see just how fibrous it is! The photo on the right is a closeup of the one on the left. It might look like a pile of folded fluffy bathroom towels, but really it’s sheets of paper! This is 100 percent recycled Evolve paper made by M-real.

Papermaking by machine

Photo: A small papermaking machine from the early 20th century. Photo by courtesy of National Institute of Standards and Technology (NIST) Photographic Collection.

How does a Fourdrinier machine work?

Fourdrinier machines are large and complex, but I’ve simplified the process greatly and color-coded it so it’s easier to understand. From wet pulp to finished roll, the paper passes through five key stages: it starts off in a large vat called the headbox (gray); begins to form into paper on the Fourdrinier table (blue); is pressed and dried by felt rollers (green); is further dried, shaped, and smoothed in the dryer (red); and is finally pressed and rolled into finished shape by the calenders (purple). The left side of the machine (as I’ve drawn it) is called the wet end; the right side is the dry end.

Photo: A detail of some of the rollers in a Fourdrinier machine. Photo by Russell Lee for the Office of War Information, courtesy of US Library of Congress.

In a bit more detail:

Photo: From logs to rolls of paper via wood pulp and the whistling wheels of a Fourdinier machine. Historic photos by Jack Delano and others, U.S. Farm Security Administration/Office of War Information, courtesy of US Library of Congress.

Who invented paper and papermaking?

Find out more

On this website

On other sites

Books

For older readers

For younger readers

Articles

Please do NOT copy our articles onto blogs and other websites

Articles from this website are registered at the US Copyright Office. Copying or otherwise using registered works without permission, removing this or other copyright notices, and/or infringing related rights could make you liable to severe civil or criminal penalties.

Text copyright © Chris Woodford 2009, 2021. All rights reserved. Full copyright notice and terms of use.

Follow us

Rate this page

Please rate or give feedback on this page and I will make a donation to WaterAid.

Save or share this page

Press CTRL + D to bookmark this page for later or tell your friends about it with:

How Paper Is Made

You gotta have fiber!

Over the centuries, paper has been made from a wide variety of materials — wood pulp, rice, water plants, cotton, even old clothes! But no matter what you use to make paper — you need “fiber.” Today’s paper fiber comes mainly from three sources — byproducts from the sawmilling process, pulpwood logs and recycled paper products. In fact, much of the paper we use every day is a blend of new and recycled fiber.

From log to pulp

Much of the paper produced in Idaho is made from “waste” — the tree parts from logging and sawmill operations that can’t be made into lumber. After harvesting, trees are cut into logs and are transported to the mill. At the mill, a debarker removes the bark from each log. The log is cut into boards of varying sizes. The wood that’s left over is then converted into wood chips, about the size of corn flakes (though not as tasty in milk!).

The wood chips are then put into “pulp digesters” where they are broken down by steam and chemicals into a gloppy pudding of cellulose fibers and other wood components. In another process, the chemicals, wood resins, and wood lignin (sort of a natural glue in the wood) are removed. The cellulose fibers are cleaned and screened many times to get them ready to be made into paper. Some papermakers use a mechanical pulping process instead, where the wood chips are literally “beaten to a pulp.”

From pulp to paper

The paper pulp (from wood chips, recycled paper, or both) is fed into the paper-making machine. A pump sprays a thin layer of the liquid paper pulp onto a moving wire screen. This screen can be up to 20 feet wide, and can travel at speeds of 60 miles per hour. That’s fast paper!

As the pulp is carried along by the screen, the water in it is removed, and the cellulose fibers become bonded together, forming paper. While the paper is still damp, it is fed through a series of heated rollers which press it and dry it. The paper is then spooled into huge rolls, cut into various sizes, and converted into paper products.

From paper to more paper

Recycling paper helps make sure we get the most out of every tree we use. And it helps keep paper from clogging up our landfills. Each time paper is recycled, the cellulose fibers get shorter, until eventually the paper won’t hold together. That’s why most “recycled” papers contain some new paper fibers mixed in with the old.

Want to make paper at home?

Borrow our paper making kit

If you’re an Idaho resident, you may borrow a paper making kit from the Idaho Forest Products Commission. It includes screens, pulp, instructions and supporting resources. You’ll provide your own blender, dishpan and towels. Your only cost is return postage. E-mail plt@Idahoforests.org.