What materials is brick made of

What materials is brick made of

Brick

Background

The term brick refers to small units of building material, often made from fired clay and secured with mortar, a bonding agent comprising of cement, sand, and water. Long a popular material, brick retains heat, with-stands corrosion, and resists fire. Because each unit is small—usually four inches wide and twice as long, brick is an ideal material for structures in confined spaces, as well as for curved designs. Moreover, with minimal upkeep, brick buildings generally last a long time.

For the above-cited practical reasons and because it is also an aesthetically pleasing medium, brick has been used as a building material for at least 5,000 years. The first brick was probably made in the Middle East, between the Tigris and Euphrates rivers in what is now Iraq. Lacking the stone their contemporaries in other regions used for permanent structures, early builders here relied on the abundant natural materials to make their sun-baked bricks. These, however, were of limited use because they lacked durability and could not be used outdoors; exposure to the elements caused them to disintegrate. The Babylonians, who later dominated Mesopotamia, were the first to fire bricks, from which many of their tower-temples were constructed.

From the Middle East the art of brickmaking spread west to what is now Egypt and east to Persia and India. Although the Greeks, having a plentiful supply of stone, did not use much brick, evidence of brick kilns and structures remains throughout the Roman Empire. However, with the decline and fall of Rome, brickmaking in Europe soon diminished. It did not resume until the 1200s, when the Dutch made bricks that they seem to have exported to England. In the Americas, people began to use brick during the sixteenth century. It was the Dutch, however, who were considered expert craftsmen.

Prior to the mid-1800s, people made bricks in small batches, relying on relatively inefficient firing methods. One of the most widely used was an open clamp, in which bricks were placed on a fire beneath a layer of dirt and used bricks. As the fire died down over the course of several weeks, the bricks fired. Such methods gradually became obsolete after 1865, when the Hoffmann kiln was invented in Germany. Better suited to the manufacture of large numbers of bricks, this kiln contained a series of compartments through which stacked bricks were transferred for pre-heating, burning, and cooling.

Brickmaking improvements have continued into the twentieth century. Improvements include rendering brick shape absolutely uniform, lessening weight, and speeding up the firing process. For example, modern bricks are seldom solid. Some are pressed into shape, which leaves a frog, or depression, on their top surface. Others are extruded with holes that will later expedite the firing process by exposing a larger amount of surface area to heat. Both techniques lessen weight without reducing strength.

However, while the production process has definitely improved, the market for brick has not. Brick does have the largest share of the opaque materials market for commercial building, and it continues to be used as a siding material in the housing industry. However, other siding materials such as

Raw Materials

Natural clay minerals, including kaolin and shale, make up the main body of brick. Small amounts of manganese, barium, and other additives are blended with the clay to produce different shades, and barium carbonate is used to improve brick’s chemical resistance to the elements. Many other additives have been used in brick, including byproducts from papermaking, ammonium compounds, wetting agents, flocculents (which cause particles to form loose clusters) and deflocculents (which disperse such clusters). Some clays require the addition of sand or grog (pre-ground, pre-fired material such as scrap brick).

A wide variety of coating materials and methods are used to produce brick of a certain color or surface texture. To create a typical coating, sand (the main component) is mechanically mixed with some type of colorant. Sometimes a flux or frit (a glass containing colorants) is added to produce surface textures. The flux lowers the melting temperature of the sand so it can bond to the brick surface. Other materials including graded fired and unfired brick, nepheline syenite, and graded aggregate can be used as well.

The Manufacturing

Process

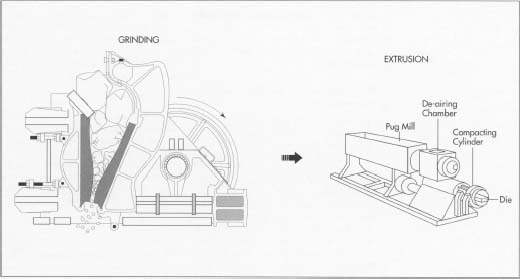

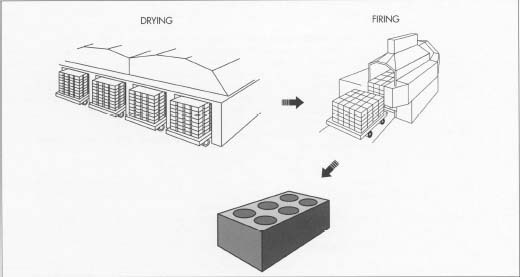

The initial step in producing brick is crushing and grinding the raw materials in a separator and a jaw crusher. Next, the blend of ingredients desired for each particular batch is selected and filtered before being sent on to one of three brick shaping processes—extrusion, molding, or pressing, the first of which is the most adaptable and thus the most common. Once the bricks are formed and any subsequent procedures performed, they are dried to remove excess moisture that might otherwise cause cracking during the ensuing firing process. Next, they are fired in ovens and then cooled. Finally, they are dehacked—automatically stacked, wrapped with steel bands, and padded with plastic corner protectors.

Grinding, sizing, and combining

raw materials

Extrusion

In molding, soft, wet clay is shaped in a mold, usually a wooden box. The interior of the box is often coated with sand, which provides the desired texture and facilitates removing the formed brick from the mold. Water can also be used to assist release. Pressing, the third type of brick forming, requires a material with low water content. The material is placed in a die and then compacted with a steel plunger set at a desired pressure. More regular in shape and sharper in outline than brick made with the other two methods, pressed bricks also feature frogs.

Chamfering the brick

Coating

Drying

Firing

Setting and packaging

Quality Control

Though the brick industry is often considered unsophisticated, many manufacturers are participating in total quality management and statistical control programs. The latter involves establishing control limits for a certain process (such as temperature during drying or firing) and tracking the parameter to make sure the relevant processes are kept within the limits. Therefore, the process can be controlled as it happens, preventing defects and improving yields.

A variety of physical and mechanical properties must be measured and must comply with standards set by the American Society of Testing and Materials (ASTM). These properties include physical dimensions, density, and mechanical strength. Another important property is freeze-thaw durability, where the brick is tested under conditions that are supposed to simulate what is encountered in the outdoors. However, current tests are inadequate and do not really correlate to actual conditions. What passes in the laboratory may not pass in the field. Therefore, the brick industry is trying to develop a more accurate test.

A similar problem exists with a condition known as efflorescence, which occurs when water dissolves certain elements (salt is among the most common) in exterior sources, mortar, or the brick itself. The residual deposits of soluble material produce surface discoloration that can be worsened by improper cleaning. When salt deposits become insoluble, the efflorescence worsens, requiring extensive cleaning. Though a brick may pass the laboratory test, it could fail in the field due to improper design or building practices. Therefore, brick companies are developing their own in-house testing procedures, and research is continuing to develop a more reliable standard test.

The Future

Currently, the use of brick has remained steady, at around seven to nine billion a year, down from the 15 billion used annually during the early 1900s. In an effort to increase demand, the brick industry continues to explore alternative markets and to improve quality and productivity. Fuel efficiency has also improved, and by the year 2025 brick manufacturers may even be firing their brick with solar energy. However, such changes in technology will occur only if there is still a demand for brick.

Even if this demand continues, the brick industry both here and abroad faces another challenge: it will soon be forced to comply with environmental regulations, especially in the area of fluorine emissions. Fluorine, a byproduct of the brickmaking process, is a highly reactive element that is dangerous to humans. Long-term exposure can cause kidney and liver damage, digestive problems, and changes in teeth and bones, and the Environmental Protection Agency (EPA) has consequently established maximum exposure limits. To lessen the dangers posed by fluorine emissions, brickworks can install scrubbers, but they are expensive. While some plants have already installed such systems, the U.S. brick industry is trying to play a more important role in developing less expensive emissions testing methods and establishing emission limits. If the brick industry cannot persuade federal regulators to lower their requirements, it is quite possible that the industry could shrink in size, as some companies cannot afford to comply and will go out of business.

Where To Learn More

Books

Bender, Willi and Frank Handle. Brick and Tile Making. Bauverlag GmbH, 1985.

Jones, J. T. and M. F. Berard. Ceramics: Industrial Processing and Testing. Iowa State University Press, 1972.

Robinson, Gilbert C. Ceramics and Glasses. ASM International, 1992, pp. 943-950.

Periodicals

«Trends in Brick Plant Operations,» The American Ceramic Society Bulletin. 1992, pp. 69-74.

Hall, Alvin. «Using Computer-Aided Manufacturing to Build Better Brick,» The American Ceramic Society Bulletin. 1990, pp. 80-82.

Richards, Robert W. «Brick Manufacturing from Past to Present,» The American Ceramic Society Bulletin. May, 1990, pp. 807-813.

Sheppard, Laurel M. «Making Brick and Meeting Regulations,» The American Ceramic Society Bulletin. 1993.

«Lodge Lane Brickworks: A Breakthrough in the Reduction Firing of Bricks,» Ziegelindustrie. September, 1992, pp. 344-341.

Composition of Bricks – Bricks are rectangular units of construction material. Bricks are used in masonry construction, walls, and pavements. It is used as a substitute for stone, where the stone is not readily available. Brick chips are often used as coarse aggregate in the concrete mix.

Abstract: This Technical Note presents fundamental procedures for the manufacture of clay brick. The types of clay used, the three principal processes for forming brick and the various phases of manufacturing, from mining through storage, are discussed. Information is provided regarding brick durability, color, texture (including coatings and glazes), size variation, compressive strength, and absorption.

Key Words: absorption, clays, color, cooling, compressive strength, de-hacking, drying, durability, firing, forming, hacking, manufacturing, mining, preparation, shales, size variation, texture.

For the preparation of bricks, clay or other suitable earth is molded to the desired shape after subjecting it to several processes. After drying, it should not shrink and no crack should develop. The clay used for brick making consists mainly of silica and alumina mixed in such a proportion that the clay becomes plastic when water is added to it. It also consists of small proportions of lime, iron, manganese, sulfur, etc. The proportions of the various ingredients are as follows:

Ingredient

Percentage in brick

Clay is one of the most abundant natural mineral materials on earth. For brick manufacturing, clay must possess

some specific properties and characteristics. Such clays must have plasticity, which permits them to be shaped or

molded when mixed with water; they must have sufficient wet and air-dried strength to maintain their shape after

forming. Also, when subjected to appropriate temperatures, the clay particles must fuse together.

Natural clay minerals, including kaolin and shale, make up the main body of brick. Small amounts of manganese, barium, and other additives are blended with the clay to produce different shades, and barium carbonate is used to improve brick’s chemical resistance to the elements. Many other additives have been used in brick, including byproducts from papermaking, ammonium compounds, wetting agents, flocculents (which cause particles to form loose clusters) and deflocculents (which disperse such clusters). Some clays require the addition of sand or grog (pre-ground, pre-fired material such as scrap brick).

A wide variety of coating materials and methods are used to produce brick of a certain color or surface texture. To create a typical coating, sand (the main component) is mechanically mixed with some type of colorant. Sometimes a flux or frit (a glass containing colorants) is added to produce surface textures. The flux lowers the melting temperature of the sand so it can bond to the brick surface. Other materials including graded fired and unfired brick, nepheline syenite, and graded aggregate can be used as well.

Chief Ingredients of Brick and Their Functions

Silica (Sand) and Alumina (Clay), these two are the most prominent ingredients in brick clay. When mixed with water in proper proportions, it gains plasticity. The plastic mass can be easily molded and dried. It should not go through cracking, shrinkage or warping.

Alumina

Alumina is the main constituent of clay. It acts as a cementing material in raw brick. Brick clay is plastic due to the presence of alumina. This plasticity ensures that bricks can be molded. An excess amount of alumina in clay may cause the bricks to shrink, warp or crack on drying and burning as any other cementing material.

Silica

Good quality bricks contain 50-60% silica. It is present in both free and combined form. As frees sand, it remains mechanically mixed with clay. In combined form, it reacts with alumina to form aluminosilicates. Silica prevents raw bricks from cracking, shrinking and warping. The higher the proportion of sand, the more and shapely and uniform in texture will be the brick. Although, excess silica destroys cohesion between the brick clay particles and makes brick brittle and weak. The durability of bricks largely depends upon the proper proportion of silica and alumina.

Bricks should contain a little amount of finely powdered lime. It enables silica (of a required portion) to melt at the furnace temperature of 1650oC and binds the particles of brick together resulting in strong and durable bricks. At about 1100o C, lime acts as a catalyst to elevate the furnace temperature to 1650oC at which silica fuses. This slightly fused silica works as a strong cementing material. Excess lime in brick clay will cause the vitrification of bricks. It causes bricks to melt, as more than the required amount of silica will fuse. The bricks then lose their shape and become disfigured.

Iron Oxide

Bricks contain a small quantity of Iron Oxide. Iron Oxide acts a flux like lime, thus helps silica to fuse at low temperatures. It imparts a red color to bricks upon burning. Iron also increases the durability and impermeability of the bricks.

Magnesia

A small proportion of magnesium decreases shrinkage and gives a yellow tint to the bricks. An excess amount of it causes bricks to decay.

Harmful Ingredients of Brick

Lime

Excess lime melts the bricks and disfigures it. If CaCO3 exists (in the purest form, i.e., if it contains at least 95% CaO) in lime-lump in brick clay, it converts into quicklime on burning. When these bricks come in contact with water, quicklime slakes and expands. And causes disintegration of bricks.

Alkalis

Alkalis are mainly salt of Sodium (Na) and Potassium (K). It acts as a flux in the kiln and causes fusion, warping, and twisting of bricks. Alkalis absorb moisture from the atmosphere and cause dampness & efflorescence in bricks (because of the presence of hygroscopic salts, e.g., CaCl2, MgCl2, etc.).

Pebbles, Stones & Gravels

Their presence does not allow thorough mixing of earth, thus the bricks produced are weaker. Such bricks cannot be broken at the desired section and they break very irregularly.

Iron Pyrites (FeS)

Iron Pyrites causes crystallization & disintegration of bricks while burning. It discolors bricks in the form of black slag.

Organic Matter

Organic matter in bricks makes bricks porous resulting in low density and weaker bricks.

What materials is brick made of

Being made from clay and shale

brick is most abundant and natural material on earth.

Bricks have been used for building innumerable structures over many thousands of years because of their durability. The reason why the brick turns into such a durable material is that, when fired through a kiln at up to 2000 degress, clay unit goes through a vitrification process which fuses the clay particles together. Unlike other materials, brick is very user and maintenance friendly creating energy efficient buildings, but also performing various functions.

The advantages of bricks are countless.

• resistant against high pressure and frost;

• is a non-combustible material;

• does not shrink and expand during fluctuation of temperature;

• can absorb heat very well;

• is reusable and recyclable;

• is available in many colours and textures.

No wonder that for centuries architects and customers have a heart for bricks. Bricks do not only resist the ravages of time but also are continuously being reinvented.

10 reasons why bricks

1. The use of natural base materials

Bricks are the result of a combination of purely natural elements: clay, sand, water, air, and fire. No toxic substances are added to bricks. In addition, bricks are inert material: it does not or hardly react to other substances and also does not release toxic substances or allergens. Therefore, there is absolutely no risk of soil pollution.

2. Economical base material policy

Clay and loam are natural and seemingly inexhaustible base materials. Excavation is limited and excavated sites reconstructed for agriculture or recreation. Starting materials are used that are released during infrastructure work and building projects in order to keep down the exploitation rate of the pits.

3. Clay extraction creates new possibilities

The excavation of clay is temporary by nature. The exploitation covers a limited surface that never grows in time, but merely moves. After extraction the site is reconstructed. This often leads to added value for the biodiversity, among other things, as a result of constructing nature reserves.

4. Environmentally friendly manufacturing processes.

5. Short transport distances

Brick kilns are often located near the quarry. This way the clay does not need to be transported across long distances. Some brick kilns sometimes add clay from other quarries in order to expand their product assortment. But even then, transport remains rather limited.

6. Long lifespan without maintenance

Bricks are made to last for generations. The average lifespan of a building made from bricks is estimated at more than 100 years. The impact of the building on the environment is also much smaller because it does not need maintenance.

7. Durable and precious

Their lifespan and limited environmental impact make bricks unbeatable if you want to build a durable building. Bricks make it possible to create beautiful buildings with limited spending and a long lifespan. Brick offers lasting value. It does not rot, dent, or need to be painted. Unlike other materials, bricks actually look better with age.

8. Comfortable and sturdy

The superior thermal mass qualities of brick have been known for centuries. Bricks keep out the weather and the wind due to their good heat absorption. What’s the secret? In winter, bricks store the heat on sunny days and then slowly release it. During the summer they buffer the heat and the brick building stays cool on the hottest days. In addition, bricks are non-flammable and solid as well as absorb noise which is an acoustic advantage over other materials.

9. Good recycling possibilities

Brick walls can be dismantled. Bricks are reusable after removing mortal residues, for example, for restoration or for the construction of new houses and projects. Also brick rubble from demolition sites can be recycled and reused. For example as:

• Filling and stabilising material for infrastructure work

• Ingredients for poured concrete and prefabricated mortar on site

• Ingredients for bricks from calcium silicate

• Red ‘grounded bricks’ (clay) on tennis courts

• Plant substrates

10. Flexibility of brick buildings

Buildings made from bricks are extremely flexible.

They can be adjusted during the entire building process and during the entire lifespan of the building. Hardly ever does a building need to be taken down because the bricks cause a problem.

5 Types of Materials Used for Bricks

Deane Biermeier is an expert contractor with nearly 30 years of experience in all types of home repair, maintenance, and remodeling. He is a certified lead carpenter and also holds a certification from the EPA. Deane is a member of The Spruce’s Home Improvement Review Board.

In the history of professional construction practices, brick is one of the oldest of all building materials. It is also arguably the most durable, since there are brick walls, foundations, pillars, and road surfaces constructed thousands of years ago that are still intact.

When asked to think of a brick building, you might conjure up an image of a red brick schoolhouse or a similar traditional structure, but «brick» doesn’t refer to a single material. In fact, bricks can be made of many different materials and for different purposes.

Here we’ll cover a range of types of brick and the uses of each.

What Is Brick?

Officially, the term «brick» is used to denote a building unit made of shaped clay, but in modern times it refers to any stone- or clay-based building unit that is joined with cementitious mortar when used in construction. Typically, bricks are about 8 inches long, 4 inches wide, and a variety of thicknesses, with variations in different countries. Larger stone- or clay-based building units as used in foundations are called «blocks.»

Advantages of Brick Construction

There are many advantages when bricks are used in construction.

Unlike wood, bricks are man-made, requiring no excavation, deforestation, or exploitation of non-renewable resources.

How Bricks Are Made

Bricks can be made in a variety of ways, often from a clay-based material, molded into shape, and then fixed in form with heat or other drying processes.

The oldest bricks used natural clay and were dried in the sun. Over time, techniques were developed to make bricks stronger and more resilient to weight, heat, weather, and erosion. Clay can be mixed with concrete, ash, or various chemicals to change the composition of brick to achieve desired qualities.

How Bricks Are Categorized

There are a number of ways that brick can be categorized. For example, you can divide brick into the types used for «facing» (exposed) vs. «backing» (structural and hidden from view), by how they are manufactured: «unfired» (air-cured) and «fired» (oven-baked), or by use: «common» bricks (used for residential construction) and «engineering» bricks (used in heftier civil projects).

Bricks can be categorized according to different features, but categories overlap and the taxonomy—though very descriptive—is imperfect.

Bricks can also be categorized according to their shape:

Categorizing Bricks by Raw Materials

In modern construction practices, bricks are categorized according to their component materials and method of manufacture. Under this classification, there are five common types.

Burnt Clay Bricks

Burnt clay bricks are the classic form of brick, created by pressing wet clay into molds, then drying and firing in kilns. This is a very old building material, and found in many of the ancient structures of the world. In appearance, these bricks are solid blocks of hardened clay, usually reddish in color.

Burnt clay bricks are typically sold in four classes, with first-class offering the best quality and most strength. These high-grade burnt clay bricks have no noticeable flaws and naturally cost more than lower classes.

When burnt clay bricks are used in walls, they require plastering or rendering with mortar. Uses for burnt clay bricks include masonry walls, foundations, and columns.

Sand Lime Bricks

Sand lime bricks (also known as calcium silicate bricks) are made by mixing sand, fly ash, and lime. Pigments may also be added for color. The mixture is then molded under pressure to form bricks. Sand lime bricks are not fired in kilns in the same manner as burnt clay bricks; instead, the materials bond together by a chemical reaction that occurs as the wet bricks dry under heat and pressure. Sand lime bricks offer advantages such as:

Sand lime bricks are most often used in structural foundations and walls, exposed brick and pillars, and, when pigment is added, for ornamental uses.

Engineering Bricks

Engineering bricks are used primarily in civil projects where strength and resilience against the elements are essential. They are clay-based and can be mixed with many other materials. What sets engineering bricks apart from other types is their extreme durability: They are fired at excessively high temperatures to produce a brick as hard as iron. They also have very low porosity and are used in places like sewers, retaining walls, manholes, foundational work, and underground tunnels, where resistance to water and frost is crucial. They come in two classes, A and B, with A offering higher compression strength and lower water absorption for the toughest conditions.

«Fire» or «refractory» bricks are also fired at extremely high temperatures and manufactured from specially formulated earth with a high aluminum oxide content in order to withstand incredible heat for use in places like chimneys, barbecues, and pizza ovens.

Concrete Bricks

Concrete bricks are made from solid concrete poured into molds. They are traditionally used in internal brickwork, but are more frequently being used in exterior work, such as facades and fences, to provide a modern or urban aesthetic. Concrete bricks can be manufactured in different colors if pigments are added during production.

Due to their durability, concrete bricks can be used in almost any type of construction, except underground, since they tend to be porous.

Fly Ash Clay Bricks

Fly ash clay bricks are manufactured with clay and fly ash—a byproduct of coal burning—fired at about 1,832°F. This type of brick is sometimes described as self-cementing, since it contains a high volume of calcium oxide and therefore expands when exposed to moisture. This tendency to expand, however, can also produce pop-out failure. Fly ash clay brick has the advantage of being lighter in weight than clay or concrete brick.

Typical uses for fly ash clay brick include:

How Are Bricks Made?

February 5th 2021

How Are Bricks Made?

Millions of bricks are manufactured each year all over the world.

But have you ever stopped to wonder how they get made?

Brickmaking has changed significantly since we first started making them. Check out our history of bricks and brickmaking for more on that.

The process has been somewhat refined over the years and now modern brick manufacturing follows a very particular process.

In this post, we’ll be going through how a typical kiln-fired brick is made.

Raw Materials

The main ingredient of most bricks is clay. It always has been.

There are particular kinds of clay minerals that are more suited to making bricks and often the location of the clay can have an impact on the colour of the end product.

What else is in a brick?

A big component of brick is the addition of sand. Many bricks also contain other additives such as Lime, Iron Oxide and Magnesia which offer other benefits.

The final crucial ingredient in the brick making process is water.

The Manufacturing Process

We now come to the manufacturing process itself.

As we mentioned above not every brick you see will be made in the format we explain below, but the vast majority of fired bricks are.

1. Crushing/Grinding

First off, the dry, raw clay material is crushed and ground in what’s called a jaw crusher. This turns the material into smaller particles and it’s at this stage that the other materials are added.

Different size pieces are separated and larger pieces are set aside for pummelling so they can be used in another batch.

2. Forming Bricks

There are a number of different options for this stage that are used around the world today.

Here’s some detail about the three most common forms of brick manufacture.

Extrusion (or Wirecut)

After crushing, the pulverised material is fed into one end of a pug mill. The material is then folded together so it’s all properly mixed.

The brick shape is formed by pushing the material through a die. This is an orifice in the end of the machine shaped into the cross section of a brick.

Sections of the desired length are then cut off with saws or wires or in some cases a long cable is formed and then cut into segments from there.

The dies allow for a certain degree of versatility in production. For example, cylindrical sections can be included to create holes in the brick.

Moulding

In larger scale manufacturing, a hydraulic press will compact the material into the required shape. The sand on the inside of the mould helps with the removal of the brick and also gives it a certain surface texture.

Pressing

This is similar to the moulded method but uses much thicker clay and greater force in pressing.

The thick clay mix has a lower water content which when pressed leads to a more accurate, sharper edged brick. The material is placed in a die and then compacted with a steel plunger. This can be set at different pressures.

This is a more expensive process, particularly as longer firing is usually required, but it creates much more durable bricks.

3. Optional Steps

After these production techniques, some manufacturers may choose to include some other steps, depending on the requirements of the brick.

These include chamfering, which involves having a roller to make an indent or apply a furrow as it exits the extruder.

Some bricks may also be coated with sand, either by a vibrating machine coater, pressure roller or for the hardest material, a sand blaster.

4. Drying

Once the brick itself has been made, it needs to dry.

Removal of excess moisture is important. If it’s not removed, it will evaporate too quickly during firing and cause cracking, thus ruining the brick.

There are a couple of ways to dry large amounts of brick. For a long time, the most common way of doing this was by using tunnel dryers.

These consist of a long chamber through which the fresh ware is slowly pushed. Fan circulated hot air is forced into the dryer covering the bricks.

Automatic chamber dryers are also in wide use. Bricks sit on extruded bars and are placed in rows where they are dried in the heavily regulated climate.

5. Firing

The next major step in making bricks is the firing process.

Generally, bricks will stay on the same cars used for the drying process to take them into the kiln. This is where firing takes place.

Kilns have evolved significantly over the years, increasing capacity, consistency and economic efficiency.

Most kilns in operation are tunnel kilns, whereby bricks are pushed through a long, specially built tunnel, whilst being fired.

They used to be high and narrow. Now they’re generally lower and wider, allowing more bricks to be fired at once.

Most bricks these days are gas fired in order to better regulate a continuous temperature. But in some cases, a coal fire may be used.

6. Unloading

The final part of the process involves allowing the bricks to cool and then be unloaded.

They are removed or ‘dehacked’ from the cars and then ‘set’ in stacks where they can then be wrapped and packaged for distribution.

We Love Bricks

If you hadn’t realised, we love bricks. And we love finding out where they come from. We hope you found this interesting too.

Maybe it’s given you a greater appreciation for the brick making process.

If this has got you in the mood for some brick browsing before Christmas, then check out our brick library section.

About Us

We believe people deserve to buy bricks happily, which is why we invest our time and skill into a customer experience which is quick and easy to use. We’d love to help you buy the best bricks for your project.

:max_bytes(150000):strip_icc()/12471747_996352377103821_6648969313298231599_o-5699c8ae5f9b58eba49febd7.jpg)

:max_bytes(150000):strip_icc()/headshots_FINAL_deane-biermeier-842c201b7d0244dbb856926dd97ed720.png)

:max_bytes(150000):strip_icc()/_DSC3035-89e8764848db4aa6901d9451b9b15923.jpeg)

:max_bytes(150000):strip_icc()/bricks-types-uses-and-advantages-844819-v4-dfd8be11b5034809aa3d9a2f117ad79b.png)