How can the ship energy efficiency management plan increase shipboard energy efficiency

How can the ship energy efficiency management plan increase shipboard energy efficiency

How can the ship energy efficiency management plan increase shipboard energy efficiency

Importance of communications between departments

One of the issues observed most of the time is the lack of optimal organizational communications between various departments that lead to a waste of energy. For example, communication between deck and engine departments is essential for machinery use optimization. In an effective shipboard energy efficiency program, the collaboration and communications between all departments need to be enhanced. It may be achieved via consideration of energy efficiency at daily meetings and relevant shipboard work planning for the reduction of electricity, compressed air, fresh water, etc. use.

Shipboard Energy Efficiency Measures

It was widely argued and shown that these kinds of measures are not fully under the control of ship staff, thus the issue of communication and coordination between ship, shore office, charterer, shipper, etc. were highlighted. In this module, energy efficiency measures are covered to a large extent under the control shipboard staff (although not all of them by 100%). They could be the subject of ship’s in-passage activities for energy efficiency. An overview of major aspects of shipboard activities that impacts the ship’s fuel consumption coming under this category is briefly introduced first and then fully described in other sections of this module.

Optimized ship handling

Optimum use of rudder and autopilot: There have been large improvements in automated heading and steering control systems technologies. While originally developed to make the bridge team more effective, modern autopilots can achieve much more. An integrated navigation system can achieve significant fuel savings by simply reducing the distance sailed «off track.» The principle is simple; better course control through less frequent and smaller corrections will minimize losses due to rudder resistance. In some cases, retrofitting of a more efficient autopilot to existing ships could be considered.Read more on

Optimised propulsion condition

Hull maintenance: Hull fouling always happens in ships. The rate of hull fouling will depend on several factors such as quality of paint, ship service speed, periods of idle /waiting, and ship geographical area of operation. Hull resistance can be optimized by new advanced coating systems, possibly in combination with hull cleaning at certain intervals. Regular in-water inspection of the condition of the hull is recommended. Consideration may be given to the possibility of timely full removal and replacement of underwater paint systems to avoid the increased hull roughness caused by repeated spot blasting and repairs over multiple dry dockings. Propeller cleaning: Propeller cleaning and polishing or even appropriate coating may significantly increase fuel efficiency. The need for ships to maintain efficiency through in-water hull and propeller cleaning should be recognized and facilitated by port States.

Read more on Energy efficiency measures- Causes of Hull roughness and preventive measures

Main engine maintenance: Marine diesel engines have a very high thermal efficiency (

50%). It is the best currently available on the market and is the main reason why diesel engines are unrivaled in shipping. The high efficiency is due to the systematic minimization of heat and mechanical loss of such engines and improved performance parameters that has taken place over many decades.

Optimised auxiliary machinery

There is a significant number of auxiliary machinery onboard ships that use electrical power to function. Such machinery has some redundancies for safety and operational purposes so that if one fails, the redundant one could take over and ensure continuous safety and operation of the ship. There aspects to the choice of such machinery as well as their operation that impact a ship’s energy efficiency. For example, the way such machinery is used could lead to poor maintenance as well as high energy use. Read more on

Maintenance and energy efficiency

Ship maintenance operations and management are fundamental for the energy-efficient operation of its machinery and systems. Deterioration of ship systems’ condition takes place due to normal wear and tear, fouling, mis-adjustments, long periods of operation outside design envelopes, etc. As a consequence, equipment downtime, quality problems, energy losses, safety hazards, or environmental pollution may result. The end outcome is a negative impact on operating cost, profitability, customer satisfaction, and probable negative environmental impacts. Thus good maintenance is in line with good performance and energy efficiency.

Technical upgrades and retrofits

There are a whole host of technologies that may be used to improve the energy efficiency of an existing ship. Although a decision to choose and install such technology upgrades is outside the hand of shipboard staff, nevertheless, this topic will be covered in this module. Typical technologies could include the following.

Technical Upgrade and Retrofit

One effective way of improving the energy efficiency of a ship is to upgrade shipboard technologies to more energy-efficient ones. Upgrading of technologies is not a shipboard activity. Nevertheless, the shipboard staff could always engage in proposing such technologies. For this reason, this topic is covered under this module.

Several technology upgrades can be considered for energy efficiency. It should be noted that the applicability of such technologies will depend on ship type, ship size, operation profile, and other factors. Thus the decision making for each technology will need to go through the normal process of technical feasibility aspects and economic cost-effectiveness analysis for the specific ship that is under consideration. The technologies described here only shows a good sample, but the list is not comprehensive as other potential technologies may be included.

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

How can the ship energy efficiency management plan increase shipboard energy efficiency

EEDI & SEEMP

The Energy Efficiency Design Index (EEDI) was made mandatory for new ships and the Ship Energy Efficiency Management Plan (SEEMP) for all ships at MEPC 62 (July 2011) with the adoption of amendments to MARPOL Annex VI (resolution MEPC.203(62)), by Parties to MARPOL Annex VI.

This was the first legally binding climate change treaty to be adopted since the Kyoto Protocol. Since this breakthrough MEPC 63 (March 2012) adopted four important guidelines (resolutions MEPC.212(63), MEPC.213(63), MEPC.214(63) and MEPC.215(63)) aimed at assisting the implementation of the mandatory regulations on Energy Efficiency for Ships in MARPOL Annex VI.

Energy Efficiency Design Index

The EEDI for new ships is the most important technical measure and it aims at promoting the use of more energy efficient (less polluting) equipment and engines. The EEDI requires a minimum energy efficiency level per capacity mile (e.g. tonne mile) for different ship type and size segments. From 1 January 2013, following an initial two year phase zero when new ship design will need to meet the reference level for their ship type, the level is to be tightened incrementally every five years, and so the EEDI is expected to stimulate continued innovation and technical development of all the components influencing the fuel efficiency of a ship from its design phase. The EEDI is a non-prescriptive, performance-based mechanism that leaves the choice of technologies to use in a specific ship design to the industry. As long as the required energy efficiency level is attained, ship designers and builders are free to use the most cost-efficient solutions for the ship to comply with the regulations. The EEDI provides a specific figure for an individual ship design, expressed in grams of carbon dioxide (CO2) per ship’s capacity-mile (the smaller the EEDI the more energy efficient ship design) and is calculated by a formula based on the technical design parameters for a given ship.

The CO2 reduction level (grams of CO2 per tonne mile) for the first phase is set to 10% and will be tightened every five years to keep pace with technological developments of new efficiency and reduction measures. Reduction rates have been established until the period 2025 to 2030 when a 30% reduction is mandated for applicable ship types calculated from a reference line representing the average efficiency for ships built between 2000 and 2010. The EEDI is developed for the largest and most energy intensive segments of the world merchant fleet and will embrace 72% of emissions from new ships covering the following ship types: oil tankers, bulk carriers, gas carriers, general cargo, container ships, refrigerated cargo and combination carriers. For ship types not covered by the current formula, suitable formulas are expected to be developed in the future addressing the largest emitters first.

Ship Energy Efficiency Management Plan and Energy Efficiency Operational Indicator

The Ship Energy Efficiency Management Plan (SEEMP) is an operational measure that establishes a mechanism to improve the energy efficiency of a ship in a cost-effective manner. The SEEMP also provides an approach for shipping companies to manage ship and fleet efficiency performance over time using, for example, the Energy Efficiency Operational Indicator (EEOI) as a monitoring tool. The guidance on the development of the SEEMP for new and existing ships incorporates best practices for fuel efficient ship operation, as well as guidelines for voluntary use of the EEOI for new and existing ships (MEPC.1/Circ.684). The EEOI enables operators to measure the fuel efficiency of a ship in operation and to gauge the effect of any changes in operation, e.g. improved voyage planning or more frequent propeller cleaning, or introduction of technical measures such as waste heat recovery systems or a new propeller. The SEEMP urges the ship owner and operator at each stage of the plan to consider new technologies and practices when seeking to optimise the performance of a ship.

2012 Guidelines on Technical and Operational Measures

Further to the adoption of a global energy standard at MEPC 62 (July 2011), MEPC 63 (March 2012) adopted four sets of important guidelines to assist in the implementation of the mandatory regulations on Energy Efficiency for Ships in MARPOL Annex VI:

2012 Guidelines on the method of calculation of the attained Energy Efficiency Design Index (EEDI) for new ships, resolution MEPC.212(63);

2012 Guidelines for the development of a Ship Energy Efficiency Management Plan (SEEMP), resolution MEPC.213(63);

2012 Guidelines on survey and certification of the Energy Efficiency Design Index (EEDI), resolution MEPC.214(63); and

Guidelines for calculation of reference lines for use with the Energy Efficiency Design Index (EEDI), resolution MEPC.215(63).

Finalization and adoption of the supporting guidelines was a significant achievement which provides sufficient lead time for Administrations and industry to prepare. The guidelines will support Member States in their uniform implementation of the new chapter 4 of MARPOL Annex VI Regulations for the prevention of air pollution from ships.

An updated work plan for the development of further guidelines and the development of energy efficiency frameworks for those ships not covered by the current EEDI regulations was also agreed at MEPC 63.

Background and further information

In accordance with the MEPC 55 work plan (October 2009), MEPC 59

(July 2009) agreed to a package of technical and operational measures to improve energy efficiency and reduce GHG emissions from international shipping: Energy Efficiency Design Index for new ships (EEDI), Ship Energy Efficiency Management Plan (SEEMP) and Energy Efficiency Operational Indicator (EEOI).

Amendments to MARPOL Annex VI were adopted by Parties to MARPOL

Annex VI during MEPC 62 in July 2011 (resolution MEPC.203(62)), adding a new chapter 4 to Annex VI on Regulations on energy efficiency for ships to make mandatory the EEDI for new ships, and the SEEMP for all ships. The regulations apply to all ships of 400 gross tonnage and above and are expected to enter into force on 1 January 2013. However, under regulation 19, an Administration may waive the requirement for new ships of 400 gross tonnage and above from complying with the EEDI requirements. This waiver may not be applied to ships above 400 gross tonnage for which the building contract is placed four years after the entry into force date of chapter 4. The amendments to MARPOL Annex VI represent the first ever mandatory global GHG regime for an international industry sector or transport mode.

The new chapter also includes a regulation on Promotion of technical co-operation and transfer of technology relating to the improvement of energy efficiency of ships, which requires Administrations, in co-operation with IMO and other international bodies, to promote and provide, as appropriate, support directly or through IMO to States, especially developing States, that request technical assistance. It also requires the Administration of a Party to co-operate actively with other Parties, subject to its national laws, regulations and policies, to promote the development and transfer of technology and exchange of information to States, which request technical assistance, particularly developing States, in respect of the implementation of measures to fulfil the requirements of chapter 4.

Model Course for energy efficient operation ships

IMO, together with the World Maritime University (WMU) have been developing a model course on SEEMP promoting the energy efficient operation of ships. The first draft of the model course was submitted to MEPC 62. It provides general background on the climate change issue and IMO’s related work and aims at building the different operational and technical tools into a manageable course programme, which will promulgate best practice throughout all sectors of the industry. The Course will help create benchmarks against which operators can assess their own performance. The purpose of the IMO model courses is to assist training providers and their teaching staff in organizing and introducing new training courses, or in enhancing, updating or supplementing existing training material, so that the quality and effectiveness of the training courses may thereby be improved.

MEPC 62 agreed that the draft model course was an excellent start to providing a structured training course but that it required more work. MEPC 63 recognized that the draft model course had been further developed to include some tutorial examples, but further work was needed to align it with the 2012 guidelines adopted at this session.

План управления энергетической эффективностью судна (ПУЭЭС)

Цель Плана управления энергетической эффективностью судна (SEEMP) заключается в создании механизма для компании и/ или судна по улучшению энергетической эффективности эксплуатации судна.

ПУЭС состоит из 3-х (трёх) частей.

ПУЭС, Часть I ( Part I ) обеспечивает повышение энергетической эффективности судна посредством цикла, состоящего из четырёх этапов: планирование, внедрение, мониторинг и самооценка с улучшением. Эти компоненты играют важную роль в непрерывном цикле постоянного улучшения управления энергетической эффективностью судна.

ПУЭС, Часть II ( Part II ) включает описание методологии, которая будет использоваться для сбора данных (план сбора данных по расходу жидкого топлива), и процедуры, которые будут применяться для предоставления данных Администрации.

ПУЭС, Часть III ( Part III ) должна включать следующее:

.2 процессы, которые будут использоваться для направления отчётов этого значения судовой администрации;

.3 требуемый ежегодный эксплуатационный коэффициент выброса углерода (CII), который будет достигаться в течение трех лет;

.4 план внедрения, фиксирующий информацию, каким образом требуемый годовой эксплуатационный коэффициент выброса углерода (СII) будет достигнут в следующие три года;

.5 процедуру самооценки и улучшения;

.6 для судов, имеющих рейтинг D в течение трех лет подряд или рейтинг Е, должен быть пересмотрен и включать план корректирующих действий для достижения требуемого годового эксплуатационного коэффициента выброса углерода (CII).

Ниже представлена таблица предлагаемых методов улучшение энергетической эффективности:

Метод улучшения

Improvement method

Описание метода

Description

Улучшенное планирование рейса

Improved voyage planning

Более тщательное планирование и выполнение рейса

Careful planning and execution of voyages.

Прогноз погоды

Weather routeing

Потенциально более выгодные маршруты, предлагаемые существующими провайдерами

Potential efficiency savings using routeing tools from existing providers.

Всё в своё время

Just in time

Оптимизация скорости хода судна с учётом предварительного взаимодействия со следующим портом по вопросу доступного причала

Optimize speed based on early communication with next port on berth availability.

Оптимизация скорости

Speed optimization

Для снижения расхода топлива необходимо учитывать оптимальные установки производителей двигателей и предполагаемого времени прибытия

To minimize fuel consumption, taking into account engine manufacturers optimal settings and arrival times/availability of berths at port.

Оптимизированная мощность на валу

Optimized shaft power

Эффективность может быть улучшена путем установки постоянной частоты вращения

Efficiency can be improved by setting constant RPM.

Оптимальный дифферент, соответствующий осадки и скорости

Optimum trim

Эксплуатация с оптимальным дифферентом для установленной осадки и скорости

Operating at optimum trim for specified draft and speed.

Оптимальный балласт

Optimum ballast

Балластировка судна для обеспечения оптимального дифферента и управляемости судна

Ballasting for optimum trim and steering conditions.

Оптимизация конструкции гребного винта

Optimum propeller and propeller inflow considerations

Возможная модернизация улучшенной конструкции винта с целью повышения эффективности его работы.

Possible retrofitting of improved propeller designs and/or inflow modifiers such as fins or ducts in order to improve efficiency.

Оптимальное использование руля и систем управления (автопилотов)

Optimum use of rudder and heading control systems (autopilots)

Сокращение пройденного расстояния посредством минимизации корректировок курса. Возможные улучшения по модернизации оптимизированной конструкции руля.

Reducing distance sailed ‘off track’ and minimizing losses caused by rudder corrections. Possible improvements through retrofitting optimized rudder designs.

Использование улучшенных систем покрытия корпуса, современной системы очистки корпуса и подводных осмотров.

Use of advanced coating systems, better management of cleaning intervals and underwater inspection.

Техническое обслуживание пропульсивной установки

Propulsion system maintenance

Постоянная минимизация тепловых и механических потерь через плановое техническое обслуживание.

Systematic minimization of heat and mechanical loss through routine maintenance and optimization.

Энергия тепловых и механических потерь

Energy heat loss

Использование выхлопных газов двигателей для производства электроэнергии или движения через валогенераторы или навесные двигатели.

Thermal heat loss from exhaust gases to generate electricity or propulsion via shaft motors.

Планирование работы флота

Fleet Operation Planning

Более эффективное использование мощностей флота и использования передового опыта.

Better utilization of fleet capacity and use of ‘best practice’.

Погрузочно-разгрузочные работы соответствуют конструкции судна и требованиям порта.

Cargo handling matched to ship and port requirements.

Судовое топливо

Ship’s fuel

Использование новых альтернативных видов топлива.

Potential use of emerging alternative fuels.

Программное обеспечение для расчета расхода топлива, использование возобновляемых энергетических технологий, использование берегового электропитания.

Computer software to calculate fuel consumption; use of renewable energy technology; use of shore power.

Компания ИБИКОН предлагает Вам услуги по разработке Плана управления энергетической эффективностью судна (ПУЭС) в рамках существующей системы управления с целью обеспечения соответствия новым требованиям Главы 4, Приложения VI, МАРПОЛ, а также судовые плакаты по энергоэффективности.

Наша компания разработала Плана управления энергетической эффективностью судна (ПУЭС) для судов, которые успешно проходят освидетельствования и получают одобрение:

В соответствии с Правилом 22А п.3 Приложения VI МАРПОЛ судно должно подать в Администрацию Флага или уполномоченную организацию данные по расходу жидкого топлива за прошедший год:

к 31 марта с целью получения Подтверждения соответствия к 31 мая:

What is Ship Energy Efficiency Management Plan?

With the growing concerns over increasing greenhouse gases and consumption of fossil fuels, the maritime industry governing body IMO has already taken positive steps by implementing the Energy Efficiency Design Index (EEDI), which monitors the amount of CO2 and harmful emissions from ships.

The idea of Energy Efficiency Design Index (EEDI) is to improve the hull design and machinery operations and to reduce the CO2 emissions by increasing the ship’s overall efficiency.

However, the SEEM plan needs to be developed and implemented by the shipowner to potentially reduce the operational cost of the ship which will eventually help in reducing the overall fuel consumption, including emissions and losses in the longer run.

What is SEEMP?

As the new concept of EEDI has been introduced for newly built ships, IMO has developed and structured a special tool called the Ship Energy Efficiency Management Plan to measure and control GHG emissions from the already existing shipping fleet.

The Ship energy efficiency Management Plan provides a practical approach for ship operators and ship management companies to manage operations and fleet efficiency performance over time using the Energy Efficiency Operational Indicator (EEOI) as a monitoring tool.

The Ship Energy efficiency management plan to improve the efficiency of the ship can be implemented in various ways such as by optimizing the speed of the vessel, making a course change to tackle rough weather, hull cleaning in dry dock, installing heat recovery methods etc. All these methods help in increasing the ship’s efficiency and optimizing the ship operation.

The SEEMP is a plan which is ship specific and has to be implemented according to the ship type, cargoes carried, ship routes, and other relevant factors. Hence, SEEMP cannot be implemented on a company or fleet level.

Even two sister ships will need to have a separate Ship Energy Efficiency Management plan as they will be operating in different conditions.

The basics of creating the SEEMP for a particular ship is to estimate and determine the current energy consumption of the vessel and implement various measure to reduce the same.

Key Features of Ship Energy Efficiency Management Plan

As said earlier, SEEMP needs to be implemented on an individual ship level. However, a company operating multiple ships must have a more comprehensive energy management policy for all ships in its fleet, which will act as a base to form the SEEMP for an individual type of ship

The primary objective of the SEEMP is to improve the overall operating efficiency of the ship on a long run by implementing correct and optimized methods for energy and fuel saving

Any ship operator will be happy to save more cost on the marine oil used as ship fuel. A critical function of the SEEMP is to implement methods which can reduce the overall fuel consumption of the ship as it leads to a reduction in air pollution and fuel cost, which is one of the significant operating cost of the vessel.

SEEMP do emphasis on reduction of greenhouse gas emissions from ships by providing methods for reducing the fuel consumption and using alternative fuel which causes less GHG emissions.

How to implement SEEMP?

SEEMP is ship specific plan which can be efficiently implemented on vessels in 4 steps:

1. Planning

Before implementation of any method, there has to be “planning” of how the process should be implemented. Planning is the most critical step for implementation of SEEMP; it essentially defines the current status of the energy used by the ship and how the current energy consumption can be reduced further, by creating and implementing an effective plan. The shipping management company has to compile the energy consumption of the ship by different forms such as the use of fuel, machinery installed, the efficiency of the machinery and systems, condition of the ship’s hull and paint, last dry-dock record etc. Once the data has been collected, the Broader Corporate energy management policy of the company is taken as base to draw the SEEMP for the ship.

2. Implementation

Once the planning for SEEMP is in place, the next important step is to identify different ways of implementing the measures which were selected during the planning. The Ship Energy Efficiency Management plant will consist of implementation methods and roles/ responsibility of the stakeholders involved (Company representative, Ship operator, Seafarers etc.).

Again, the implementation system has to be drawn during the planning stage to ensure smooth execution of SEEMP on the ship at the earliest.

The company’s corporate energy management policy can come very handy if the implementation methods are specified in the same. This set method of implementation can be used during establishing SEEMP on an individual ship. Record keeping should be a part of all the stages post-planning stage as the records were taken during the implementation stage can be used for the later stage of self-evaluation, which will help in improvising the plan.

3. Monitoring

Once the SEEMP is implemented on a ship, the monitoring of the plan will come into action, which will observe the effectiveness of the implemented SEEMP. There are pre-determined approved methods of international standards available to monitor the performance of SEEMP such as EEOI (as per the Guidelines developed by the IMO – MEPC.1/Circ.684).

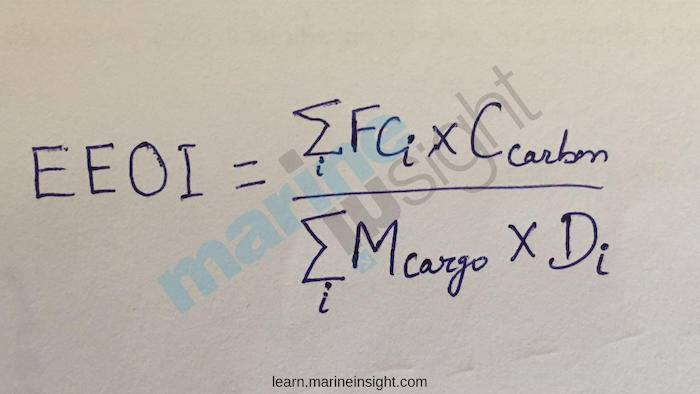

EEOI is Energy Efficiency operational indicator which can be determined by the fuel consumption of the ship in a particular voyage carrying a certain amount of cargo.

To calculate the EEOI, the following data is needed:

Where j is the fuel type

I is the voyage number

FCi is the mass of fuel consumed during the voyage

Mcargo is mass of cargo carried in tonnes

Di is the nautical miles distance for the cargo carried

Ccarbon is mass of the fuel to CO2 mass conversion factor of the fuel.

Other methods for measurement and monitoring can also be used if the company seems it is useful.

In the planning stage, the monitoring method can be stated and how to use the method can also be established making it easier for the user (seafarers and operators) to implement the system and to know his/her responsibility within the system.

4. Self-evaluation and improvement

The result of Monitoring stages needs to be evaluated to understand the effectiveness of the SEEMP which will be done at the last stage. This stage highly depends on the constructive feedback which can be assessed to improvise the plan if needed, and the same is used to enhance the planning, implementation and monitoring stages. These four stages work in a cycle and are interdependent for the evaluation and evolution of the complete SEEMP. It is the responsibility of the ship operator to ensure the feedbacks, results, and reports that came from different stages of the SEEMP cycle are tracked and assessed and the output from them is used to improvise the plan.

The other focused area of SEEMP is to reduce GHG emissions while increasing operational efficiency of the ship, resulting in less fuel consumption. Following steps are taken to achieve efficient operation of the vessel under SEEMP:

• Speed optimization:

The speed of the ship determines the amount of fuel the main engine will use to propel the ship. An optimized speed is a speed at which the fuel consumption decreases without hampering the ETA to the next port. Slow steaming has been a proven strategy to reduce the fuel consumption of the ship saving hundreds of dollars in fuel cost to the owner. However, there are other problems associated with slow steaming, hence optimum speed Is determined by keeping all the factors in mind.

Charter Party do play an important role as there agreements will allow ship operator to run the ship at optimized speed to achieve greater energy efficiency from the ship’s machinery.

• Weather routing

It is fascinating how ship tackles big storms out at sea. There have been no significant accidents lately of ship damages or sinking due to storms and rough weather as nowadays weather routing use advanced technology to predict the upcoming weather and to alter the course of the ship.

This technology is very useful and helps in the energy efficiency of the ship as rough weather can slow down a ship and the engine needs to put more power to propel against the tide or wind, leading to more fuel consumption. With weather routing, an altered course can solve this problem, making it safer for the ship’s crew and cargo and also saving fuel and increasing the energy efficiency of the ship.

• Hull monitoring and maintenance

Hull roughness of the ship is inversely proportional to the speed of the ship. This means that the engine of the ship has to work more to achieve the desired speed if the hull is rough.

The hull roughness of the ship is analysed at regular intervals for cleaning and painting of the surface. A better and advanced system such as MGPS can reduce the marine growth on the hull and improve the overall energy efficiency of the ship

• Efficient cargo operation

The cargo operation at the port is a teamwork between the ship, port, agents and other parties involved (PSC, coast guard etc.). Good and clear communication between them will ensure smoother cargo operation, leading to less time in port. This will help the ship to maintain the ETA for the other ports otherwise the ship has to sail at a higher speed for the next call which will lead to additional fuel consumption, affecting the energy efficiency of the ship.

• Electric power management

The ship’s electrical power plant generates enough energy to ensure all the propulsion, cargo, and other auxiliary equipment can be operational at any given time. The use of a generator at low load, use of multiple pumps etc., will lead to more fuel and electrical consumption, affecting the energy efficiency. The seafarers need to be trained on how to use ship’s machinery effectively so that the power consumption will be at an optimum level.

Role of Seafarers in SEEMP:

Seafarers play a crucial role in implementing the SEEMP onboard ship and also in providing the feedback, reports, performance etc. to the shore office which is further used to enhance the plan.

Following are some of the essential roles which a seafarer plays in SEEMP:

• Implementing the procedure as laid down in the SEEMP

• Monitoring the performance of the SEEMP procedures and how it is affecting the ship operation

• Collecting reports, and sending the logs, performance etc. to the company for evaluation

• Establishing a safety and sustainability culture onboard ship to add to the energy efficiency of the ship

• Efficiently managing the cargo operation when in port and maintaining the ship’s machinery to avoid breakdown and delays to the shipping schedule

• Implementing correct and modern navigation technique for the optimized voyage planning

SEEMP is not a set rule of operations and it has to evolve in terms of providing better energy saving solutions than the previous ones. The improvisation of SEEMP highly depends on the different parties involved in the shipping operation such as Port operator, Ship owners, shipyard, ship managers, seafarers etc.

Ship Energy Efficiency Management Plan (SEEMP)

All ships 400 gross tonnage (GT) and above engaged in international voyages must develop and keep on board a SEEMP, as set out in the guidelines adopted by the IMO. The SEEMP may form part of the ship’s safety management system and is subject to audit and verification.

Each SEEMP is ship-specific and provides a practical approach for ship owners and operators to manage operations and improve efficiency performance over time. For companies with multiple ships, a comprehensive energy management policy for the company’s fleet can act as a base to form individual SEEMPs for each ship.

Platforms, including floating production storage and offloading units (FPSOs) and floating storage units (FSUs), and drilling rigs are not required to have a SEEMP.

Part one of the SEEMP is for monitoring and improving the ship’s energy efficiency. It must include an estimate of the current energy consumption of the ship and identify measures to improve the ship’s efficiency, such as:

Setting an efficiency goal is a key part of developing a SEEMP. The goal should create incentive for energy efficiency improvement. The goal can take any form, such as annual fuel consumption or the Energy Efficiency Operational Indicator (EEOI)—a monitoring tool developed by IMO to measure the energy efficiency of a ship and assess the impact of operational efficiency measures.

SEEMP Part II – fuel oil consumption data

Part two of the SEEMP only applies to ships that are 5,000 GT and above and engaged in international voyages. This part of the SEEMP must include a description of how annual fuel oil consumption data for the ship will be collected and reported to their flag State.

SEEMP Part III – ship operational carbon intensity plan (in development)

From 1 January 2023 new requirements will apply to ships that are required to keep part two of the SEEMP. From this date, the SEEMP must detail how the ship’s operational carbon intensity will be calculated and improved under the new short-term MARPOL measure to reduce greenhouse gas emissions from international ships, including:

The IMO is currently revising the 2016 Guidelines for the development of a SEEMP, including the development of a new Part III on how the information related to the new short-term greenhouse gas reduction measure will be recorded in the SEEMP. The revised guidelines are expected in mid 2022.

International Energy Efficiency Certificate

All ships 400 GT and above engaged in international voyages must be issued with a ship-specific International Energy Efficiency (IEE) Certificate. This certificate must be available on board for inspections and audits.

The IEE Certificate verifies the ship’s attained Energy Efficiency Design Index (EEDI) and confirms that the ship has a SEEMP on board.

The IEE Certificate is valid for the life of the ship.

For new ships, the IEE Certificate is issued during the initial survey before the ship begins operating. For existing ships, the certificate should have been issued following the first intermediate or renewal survey after 1 January 2013.

From 1 January 2023 the IEE Certificate will also verify the ship’s attained Existing Energy Efficiency Index (EEXI). Verfication of the ship’s attained EEXI is to occur following the first annual, intermediate or renewal survey on or after 1 January 2023. Following this verification, ships will be issued or re-isisued with an IEE Certificate in the new format.

Recognised Organisations have been authorised to issue the certificates for Australian ships.

IMO resources on the SEEMP

For further information on the SEEMP requirements, please refer to MARPOL Annex VI and the 2016 Guidelines for the development of a ship energy efficiency management plan (SEEMP) (MEPC.282(70)).

Источники информации:

- http://www.marpol-annex-vi.com/eedi-seemp/

- http://ibicon.ru/plan-upravleniya-energeticheskoy-effektivnostyu-sudna

- http://www.marineinsight.com/maritime-law/what-is-ship-energy-efficiency-management-plan/

- http://www.amsa.gov.au/marine-environment/air-pollution/ship-energy-efficiency-management-plan-seemp