How to reduce sox emissions дельта

How to reduce sox emissions дельта

How to reduce sox emissions дельта

The below is applies to all vessels except those equipped with abatement technology that limits Sulphur Oxide (SOx) emissions to the regulated levels.

MARPOL 73/78 Annex VI applies to all ships flying a flag of a country that has ratified MARPOL Annex VI or ships in territorial waters of such a country.

No later than 2018, the IMO will review the feasibility of application of the lower sulphur limit, taking into account the considerations put forward by a panel of experts relating to market supply/demand scenarios, alternate date of application 2025

The Bunker Delivery Note (BDN) must mention the Sulfur content, grade of oil, IMO number of vessel, amongst other things and is required to be retained on board for 3 years.

The corresponding Fuel oil sample (called MARPOL sample) is to be retained on board for 1 year.

When the ships are within SECA (SOx Emission Control Area), the Sulfur content of any fuel oil should not exceed 1.5%.

Vessel is to maintain records of changeover calculation from normal to low sulfur fuel to prove that sufficient time had been allowed to flush the fuel oil systems of all fuels exceeding 1.5% sulfur content at the time of entry into SECA zone.

Local Air Emission Regulations (CARB): California (USA) has implemented local regulation covering their coastline out to 24 nm.

When vessel is in this area, its auxiliary diesel engine must operate on either Gas oil or Diesel oil with a sulfur content of less than 0.5%

From 1st January 2012, vessels coming into Turkish ports not permitted to use marine diesel with a sulphur content exceeding 0.1% by mass. Also, vessels with Turkish Flag can not use marine fuels whose sulphur content exceeds 1,5% in SOx Emission Detection Fields determined by IMO in accordance with Marpol Annex-VI. Likewise, Passenger Vessels sailing in Turkey’s marine jurisdiction cannot use marine fuels whose Sulphur content exceeds 1.5% by mass.

No later than 2018, the IMO will review the feasibility of application of the lower sulphur limit, taking into account the considerations put forward by a panel of experts relating to market supply/demand scenarios, alternate date of application 2025

The US Environmental Enforcement Agency (EPA) has announced that it will hold trial of vessel fly-overs to monitorcompliance with MARPOL Annex VI. Initially undergoing trials in the upper Chesapeake Bay area, it is expected that the fly-over programme will be extended to include other areas which fall under the North America Emission Control Area (NA ECA). The fly-overs will be monitoring and testing emissions from vessels to ensure the fuel oil being used on board contains less than 1% maximum sulphur content, as required by the ECA.

The North American ECA has been in force since August 1, 2012. The maximum sulphur content permissible is to be reduced even further (to 0.1%) by January 1, 2015. The new fly-over trials support further targeting by EPA and USCG to ensure vessels are compliant with the MARPOL Annex VI rules as the one year anniversary of the ECA implementation approaches. Members are advised to ensure fuel oil changeover procedures are in place, and that proper records, logs and fuel sampling are being carried out on board.

Best practices for SOx emissions control

Applying the key elements of experience gained since the introduction of SOx-reducing additives for FCC operations

Ray Fletcher

Intercat

SOx-reducing additives were first introduced into the FCC world in 1984 by Arco Refining. Clean air legislation enforced by the Environmental Protection Agency required FCC units operating with the US to begin introducing SOx-reducing additives as one of the best available control technologies. The use of these additives quickly spread throughout the refineries in North America.

A substantial body of experience has been accumulated within the industry since SOx additives were first injected into FCC units. This experience spans a very wide range of operations, including “mild reductions”, in which modest levels of SOx reductions were required, up to and including ultra-deep reductions to 5 ppm or less. These operations span full-, partial- and two-stage combustion regenerators.

Refineries operating in strict compliance zones have been required to reduce SOx emissions for decades. Some refiners have chosen the path of large capital investment via the installation of catalytic feed hydrotreaters or flue gas scrubbers to control SOx emissions. Many refiners have chosen to use additives as a capital-free route to control emissions.

As regulations spread more widely, many refiners are now being required to reduce SOx emissions. This article is intended to enable these refiners to take advantage of the experience accumulated within the industry and crystallises the most useful lessons learned since the mid-1980s.

The term SOx is used throughout this article to represent total oxidised sulphur in the form of SO2 plus SO3, which is emitted from the FCC flue gas stack.

SOx emissions chemistry

The reactions related to sulphur combustion are well understood. A simplified overview of these reactions is helpful in understanding how to control SOx emissions within the FCC regenerator.

In full-combustion operations, 100% of the sulphur contained within the coke will be oxidised. Approximately 90% of this oxidised sulphur will be in the form of SO2, with the remainder being oxidised to SO3. SOx-reducing additives absorb SO3. Most SOx-reducing additives contain cerium, which functions as an “oxygen sponge” and catalyses SO2 to SO3. The SO3 is then reacted with magnesium-forming magnesium sulphate. The magnesium sulphate is transported into the reducing atmosphere of the reactor vessel, where sulphur is released as H2S. The magnesium is then regenerated to MgO and is available for additional absorption reactions within the regenerator. These reactions are:

SO2 + ½ O2 → SO3 (2)

SO3 + MgO → MgSO4 (3)

MgSO4 + 8[H] → MgO + H2S + 3H2O (4)

Sulphur combustion within the partial-combustion regenerator is very similar to combustion within the full-burn regenerator. The notable exception is insufficient oxygen to fully oxidise the sulphur to SO2. A portion of the sulphur will be partially oxidised to COS, as shown below:

S + CO → COS (5)

COS + H2O → CO2 + H2S (6)

Two-stage regenerators are unique in that the first stage operates in partial combustion, while the second stage normally operates in full combustion. The first-stage regenerator’s sulphur combustion reactions are dominated by reactions 1 and 5, while in the second-stage regenerator reactions 1 and 2 predominate.

Predicting SOx emissions

Development of an accurate uncontrolled SOx emissions model is the first step when initiating a SOx additive trial. Baseline data are used to develop a correlation that accurately predicts SOx emissions. The additive of choice is then injected into the unit. SOx emissions will drop rapidly as the additive begins to circulate within the unit. The correlation is used to calculate the uncontrolled SOx emissions for comparison with observed emissions. This enables the process engineer to calculate the efficiency of the SOx reduction and additive.

SOx emissions will correlate with feed sulphur in some but not all units (see Figure 1). The sulphur present within the FCC feedstock partitions differently between coke and liquid products, depending on the type of sulphur molecules present within each feedstock. Those refiners experiencing frequent feed slate variation will generally have difficulty using the feed sulphur correlation.

A better correlation developed by the engineers of Gulf Oil correlates coke sulphur to slurry sulphur within a power function, as shown below:

Coke S = UF * (slurry S) 1.265 (6)

The unit factor (UF) and the exponential term are typically modified to match the operating data. The Gulf correlation is often the most accurate tool for predicting coke sulphur. Unfortunately, though, the Gulf correlation does not fit the data from every unit. In these instances, the process engineer is required to investigate other correlations (multivariable linear regressions, and so on) for more accurate matching of the baseline data.

Figure 2 demonstrates graphically how two separate units were able to correlate flue gas SOx emissions extremely well using the Gulf correlation. In Figure 1, the feed sulphur correlation has a variation of up to 200 ppm, while the Gulf correlation in Figure 2 has a variation of approximately 10 ppm.

IMO Answers Questions on the 2020 SOx Regulation

Published Feb 3, 2018 6:10 PM by The Maritime Executive

The IMO has launched a document answering frequently asked questions about the upcoming sulfur emissions regulations taking effect in 2020.

IMO regulations to SOx emissions from ships first came into force in 2005, under Annex VI of the MARPOL Convention. Since then, the limits on sulfur oxides have been progressively tightened. From January 1, 2020, the limit for sulfur in fuel oil used on board ships operating outside designated emission control areas will be reduced to 0.50 percent m/m (mass by mass). This will significantly reduce the amount of sulfur oxides emanating from ships and should have major health and environmental benefits for the world, particularly for populations living close to ports and coasts, says the IMO.

Answers to some frequently asked questions are:

Limiting SOx emissions from ships will have a very positive impact on human health: how does that work?

Simply put, limiting sulfur oxides emissions from ships reduces air pollution and results in a cleaner environment. Reducing SOx also reduces particulate matter, tiny harmful particles which form when fuel is burnt.

A study on the human health impacts of SOx emissions from ships, submitted to IMO’s Marine Environment Protection Committee (MEPC) in 2016 by Finland, estimated that by not reducing the SOx limit for ships from 2020, the air pollution from ships would contribute to more than 570,000 additional premature deaths worldwide between 2020-2025.

So a reduction in the limit for sulfur in fuel oil used on board ships will have tangible health benefits, particularly for populations living close to ports and major shipping routes.

Why are ships already less harmful than other forms of transport?

Ships do emit pollutants and other harmful emissions. But they also transport large quantities of vital goods across the world’s oceans – and seaborne trade continues to increase. In 2016, ships carried more than 10 billion tons of trade for the first time, according to UNCTAD.

So ships have always been the most sustainable way to transport commodities and goods. And ships increasingly becoming even more energy efficient. IMO regulations on energy efficiency support the demand for ever greener and cleaner shipping. A ship which is more energy efficient burns less fuel so emits less air pollution.

It has sometimes been quoted that just a few ships (all using fuel oil with maximum permitted sulfur content) emit as much harmful air pollutants as all the cars in the world (if the cars were all using the cleanest fuel available).

Not only is this the very worst case scenario, but this does not take into account the amount of cargo that is being carried by those ships and the relative efficiency. It is important to consider the amount of cargo carried and the emissions per tonne of cargo carried, per kilometer traveled. Studies have shown that ships are by far the most energy-efficient form of transportation, compared with other modes such as aviation, road trucks and even railways.

It is also relevant to remember that shipping responds to the demands of world trade. As world trade increases, more ship capacity will be needed.

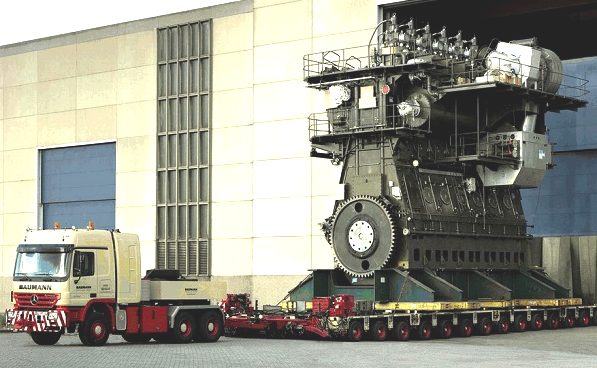

How can ships carry so much cargo so efficiently?

Ships are the largest machines on the planet and the world’s largest diesel engines can be found on cargo ships. These engines can be as tall as a four-storey house, and as wide as three London buses. The largest marine diesel engines have more than 100,000 horsepower (in comparison, a mid-sized car may have up to 300 horsepower). But the largest container ships can carry more than 20,000 containers and the biggest bulk carriers can carry more than 300,000 tons of commodities, like iron ore.

So powerful engines are needed to propel a ship through the sea. And it is important to consider how much energy is used to carry each ton of cargo per kilometer. When you look at the relative energy efficiency of different modes of transport, ships are by far the most energy efficient.

Ships can reduce air pollutants by being even more energy efficient, so they burn less fuel and therefore their emissions are lower.

What is the current regulation on SOx in ships emissions, and by how much is that going to be improved?

We are going to see a substantial cut: to 0.50 percent m/m (mass by mass) from 3.50 percent m/m.

For ships operating outside designated emission control areas the current limit for sulfur content of ships’ fuel oil is 3.50 percent m/m.

The new limit will be 0.50 percent m/m which will apply on and after January 1, 2020.

There is an even stricter limit of 0.10 percent m/m already in effect in emission control areas (ECAS) which have been established by IMO. This 0.10 percent m/m limit applies in the four established ECAS: the Baltic Sea area; the North Sea area; the North American area (covering designated coastal areas off the U.S. and Canada); and the U.S. Caribbean Sea area (around Puerto Rico and the United States Virgin Islands).

Fuel oil providers already supply fuel oil which meets the 0.10 percent m/m limit (such as marine distillate and ultra low sulfur fuel oil blends) to ships which require this fuel to trade in the ECAs.

What must ships do to meet the new IMO regulations?

The IMO MARPOL regulations limit the sulfur content in fuel oil. So ships need to use fuel oil which is inherently low enough in sulfur, in order to meet IMO requirements.

Some ships limit the air pollutants by installing exhaust gas cleaning systems, also known as “scrubbers”. This is accepted by flag States as an alternative means to meet the sulfur limit requirement.

Ships can have engines which can use different fuels, which may contain low or zero sulfur. For example, liquefied natural gas or biofuels.

Could the 0.50 percent limit be delayed?

No. There can be no change in the January 1, 2020 implementation date, as it is too late now to amend the date and for any revised date to enter into force before January 1, 2020.

Will new fuels be needed to meet the 2020 limit? Will there be enough?

It is likely that new blends of fuel oil for ships will be developed, For example, a gas oil, with a very low sulfur content can be blended with heavy fuel oil to lower its sulfur content.

These new blends are likely to cost more initially than the heavy fuel oil bunker fuel used by the majority of ships today. Ships can also choose to switch to a different fuel altogether. Or they may continue to purchase heavy fuel oil, but install scrubbers to reduce the output of SOx in order to have an equivalent means to meet the requirement.

Of course, some ships are already using low sulfur fuel oil to meet the even more stringent limits of 0.10 percent m/m when trading in the already-established emission control areas. So those fuel oil blends suitable for ECAS, will also meet the 0.50 percent m/m limit in 2020. However, there is a cost differential, and these blends are more expensive than heavy fuel oil.

A study commissioned by IMO into the «Assessment of fuel oil availability» concluded that the refinery sector has the capability to supply sufficient quantities of marine fuels with a sulfur content of 0.50% m/m or less and with a sulfur content of 0.10 percent m/m or less to meet demand for these products, while also meeting demand for non-marine fuels.

Consistent compliance with the new limit is vital. What is IMO doing about that?

Monitoring, compliance and enforcement of the new limit falls to Governments and national authorities of Member States that are Parties to MARPOL Annex VI. Flag States and port States have rights and responsibilities to enforce compliance.

IMO is working with Member States as well as industry (including the shipping industry and the bunker supply and refining industry) to identify and mitigate transitional issues so that ships may meet the new requirement.

For example, developing guidance, developing standardized formats for reporting fuel oil non availability if a ship cannot obtain compliant fuel oil and considering verification and control issues.

How to reduce sox emissions дельта

Pleas use our A-Z INDEX to navigate this site

EPA’s national ambient air quality standards for SO2 are designed to protect against exposure to the entire group of sulfur oxides (SOx). SO2 is the component of greatest concern and is used as the indicator for the larger group of gaseous sulfur oxides (SOx). Other gaseous SOx (such as SO3) are found in the atmosphere at concentrations much lower than SO2.

The largest source of SO2 in the atmosphere is the burning of fossil fuels by power plants and other industrial facilities. Smaller sources of SO2 emissions include: industrial processes such as extracting metal from ore; natural sources such as volcanoes; and locomotives, ships and other vehicles and heavy equipment that burn fuel with a high sulfur content.

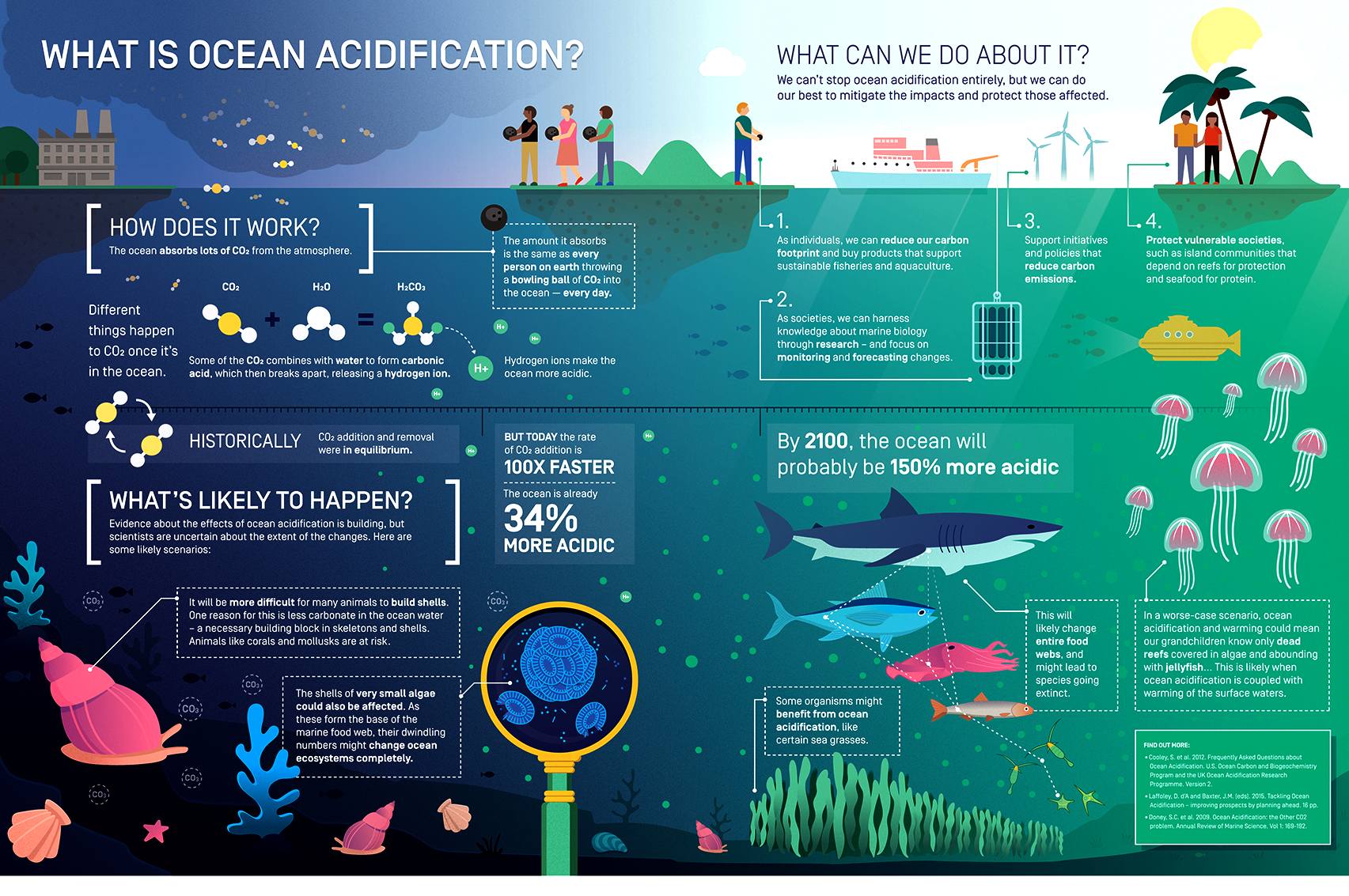

Human activities such as agriculture, fuel combustion and industrial processes are increasing the amount of sulfurous oxides in the atmosphere with catastrophic results in the acidification of our oceans and air pollution that is harmful to humans.

Sulfur (sulphur) dioxide is the chemical compound with the formula SO2. It is a toxic gas responsible for the smell of burnt matches. It is released naturally by volcanic activity and is produced as a by-product of copper extraction and the burning of fossil fuels contaminated with sulfur compounds.

Sulfur dioxide is an intermediate in the production of sulfuric acid, being converted to sulfur trioxide, and then to oleum, which is made into sulfuric acid. Sulfur dioxide for this purpose is made when sulfur combines with oxygen. The method of converting sulfur dioxide to sulfuric acid is called the contact process. Several billion kilograms are produced annually for this purpose.

On other planets, it can be found in various concentrations, the most significant being the atmosphere of Venus, where it is the third-most significant atmospheric gas at 150 ppm. There, it condenses to form clouds, and is a key component of chemical reactions in the planet’s atmosphere and contributes to global warming. It has been implicated as a key agent in the warming of early Mars, with estimates of concentrations in the lower atmosphere as high as 100 ppm, though it only exists in trace amounts. On both Venus and Mars, as on Earth, its primary source is thought to be volcanic. The atmosphere of Io, a natural satellite of Jupiter, is 90% sulfur dioxide and trace amounts are thought to also exist in the atmosphere of Jupiter.

Sulfur dioxide is a major air pollutant and has significant impacts upon human health. In addition, the concentration of sulfur dioxide in the atmosphere can influence the habitat suitability for plant communities, as well as animal life.

Sulfur dioxide emissions are a precursor to acid rain and atmospheric particulates. Due largely to the US EPA’s Acid Rain Program, the U.S. has had a 33% decrease in emissions between 1983 and 2002. This improvement resulted in part from flue-gas desulfurization, a technology that enables SO2 to be chemically bound in power plants burning sulfur-containing coal or oil. In particular, calcium oxide (lime) reacts with sulfur dioxide to form calcium sulfite:

CaO + SO2 → CaSO3

Fuel additives such as calcium additives and magnesium carboxylate may be used in marine diesel engines to lower the emission of sulfur dioxide gases into the atmosphere.

As of 2006, China was the world’s largest sulfur dioxide polluter, with 2005 emissions estimated to be 25,490,000 short tons (23.1 Mt). This amount represents a 27% increase since 2000, and is roughly comparable with U.S. emissions in 1980.

The main type of “bunker” oil for ships is heavy fuel oil, derived as a residue from crude oil distillation. Crude oil contains sulphur which, following combustion in the engine, ends up in ship emissions. Sulphur oxides (SOx) are known to be harmful to human health, causing respiratory symptoms and lung disease. In the atmosphere, SOx can lead to acid rain, which can harm crops, forests and aquatic species, and contributes to the acidification of the oceans.

Limiting SOx emissions from ships will improve air quality and protects the environment.

IMO regulations to reduce sulphur oxides (SOx) emissions from ships first came into force in 2005, under Annex VI of the International Convention for the Prevention of Pollution from Ships (known as the MARPOL Convention). Since then, the limits on sulphur oxides have been progressively tightened.

From 1 January 2020, the limit for sulphur in fuel oil used on board ships operating outside designated emission control areas will be reduced to 0.50% m/m (mass by mass). This will significantly reduce the amount of sulphur oxides emanating from ships and should have major health and environmental benefits for the world, particularly for populations living close to ports and coasts.

Below you will find answers to some of the frequently asked questions about the sulphur limit.

Symposium on IMO 2020 and Alternative Fuels (17-18 October 2019)

IMO is hosting a Symposium on IMO 2020 and Alternative Fuels on Thursday, 17 October and Friday, 18 October 2019 in the Main Hall at IMO Headquarters. This one and half day symposium aims to raise awareness and to take stock of the preparations for the IMO 2020 rule, and to discuss the role of alternative fuels in the decarbonization of international shipping.

The Symposium will be live-streamed and remote participation is open to Member Governments, IGOs, NGOs and the general public.

Member Governments, IGOs, NGOs can register delegates to attend the symposium. The symposium is also open to delegates who wish to attend the symposium but who are not affiliated with an IMO delegation.

Further details and a provisional agenda can be found in Circular letter No.3998.

Limiting SOx emissions from ships will have a very positive impact on human health: how does that work?

Simply put, limiting sulphur oxides emissions from ships reduces air pollution and results in a cleaner environment. Reducing SOx also reduces particulate matter, tiny harmful particles which form when fuel is burnt.

A study on the human health impacts of SOx emissions from ships, submitted to IMO’s Marine Environment Protection Committee (MEPC) in 2016 by Finland, estimated that by not reducing the SOx limit for ships from 2020, the air pollution from ships would contribute to more than 570,000 additional premature deaths worldwide between 2020-2025.

Why are ships already less harmful than other forms of transport?

Ships do emit pollutants and other harmful emissions. But they also transport large quantities of vital goods across the world’s oceans – and seaborne trade continues to increase. In 2016, ships carried more than 10 billion tons of trade for the first time, according to UNCTAD.

So ships have always been the most sustainable way to transport commodities and goods. And ships increasingly becoming even more energy efficient. IMO regulations on energy efficiency support the demand for ever greener and cleaner shipping. A ship which is more energy efficient burns less fuel so emits less air pollution.

It has sometimes been quoted that just a few ships (all using fuel oil with maximum permitted sulphur content) emit as much harmful air pollutants as all the cars in the world (if the cars were all using the cleanest fuel available).

Not only is this the very worst case scenario, but this does not take into account the amount of cargo that is being carried by those ships and the relative efficiency. It is important to consider the amount of cargo carried and the emissions per tonne of cargo carried, per kilometre travelled. Studies have shown that ships are by far the most energy-efficient form of transportation, compared with other modes such as aviation, road trucks and even railways.

It is also relevant to remember that shipping responds to the demands of world trade. As world trade increases, more ship capacity will be needed.

How can ships carry so much cargo so efficiently?

Ships are the largest machines on the planet and the world’s largest diesel engines can be found on cargo ships. These engines can be as tall as a four-storey house, and as wide as three London buses. The largest marine diesel engines have more than 100,000 horsepower (in comparison, a mid-sized car may have up to 300 horsepower). But the largest container ships can carry more than 20,000 containers and the biggest bulk carriers can carry more than 300,000 tons of commodities, like iron ore.

So powerful engines are needed to propel a ship through the sea. And it is important to consider how much energy is used to carry each ton of cargo per kilometre. When you look at the relative energy efficiency of different modes of transport, ships are by far the most energy efficient.

Ships can reduce air pollutants by being even more energy efficient, so they burn less fuel and therefore their emissions are lower.

State of the art Wartsila diesel engines for oil tankers and cruise liners may soon become an outdated technology as solar and wind powered vessels become economically viable due to clean air laws. Our patent energy harvesting system may soon herald in zero carbon cargo vessels and cruise liners.

What is the current regulation on SOx in ships emissions and by how much is that going to be improved?

We are going to see a substantial cut: to 0.50% m/m (mass by mass) from 3.50% m/m.

For ships operating outside designated emission control areas the current limit for sulphur content of ships’ fuel oil is 3.50% m/m.

The new limit will be 0.50% m/m which will apply on and after 1 January 2020.

There is an even stricter limit of 0.10% m/m already in effect in emission control areas (ECAS) which have been established by IMO. This 0.10% m/m limit applies in the four established ECAS: the Baltic Sea area; the North Sea area; the North American area (covering designated coastal areas off the United States and Canada); and the United States Caribbean Sea area (around Puerto Rico and the United States Virgin Islands).

(Countries bordering the Mediterranean Sea are currently considering the possibility of applying to designate the Mediterranean Sea or parts thereof as an ECA.)

Fuel oil providers already supply fuel oil which meets the 0.10% m/m limit (such as marine distillate and ultra low sulphur fuel oil blends) to ships which require this fuel to trade in the ECAs.

What must ships do to meet the new IMO regulations?

The IMO MARPOL regulations limit the sulphur content in fuel oil. So ships need to use fuel oil which is inherently low enough in sulphur, in order to meet IMO requirements.

Refineries may blend fuel oil with a high (non-compliant) sulphur content with fuel oil with a sulphur content lower than the required sulphur content to achieve a compliant fuel oil. Additives may be added to enhance other properties, such as lubricity.

Some ships limit the air pollutants by installing exhaust gas cleaning systems, also known as “scrubbers”. This is accepted by flag States as an alternative means to meet the sulphur limit requirement. These scrubbers are designed to remove sulphur oxides from the ship’s engine and boiler exhaust gases. So a ship fitted with a scrubber can use heavy fuel oil, since the sulphur oxides emissions will be reduced to a level equivalent to the required fuel oil sulphur limit.

Ships can have engines which can use different fuels, which may contain low or zero sulphur. For example, liquefied natural gas, or biofuels.

Are low sulphur blend fuel oils safe? Can new low sulphur fuels cause problems for a ship’s engine?

All fuel oil for combustion purposes on a ship must meet required fuel oil quality standards, as set out in IMO MARPOL Annex VI (regulation 18.3). For example, the fuel oil must not include any added substance or chemical waste that jeopardizes the safety of ships or adversely affects the performance of the machinery.

IMO is currently discussing how to identify any potential safety issues related to new blends of fuel oil as it is recognized that if these fuels are not managed appropriately, there could be compatibility and stability issues. If needed, additional guidance for crew and ship operators could be developed.

An International Standardization Organization (ISO) standard (ISO 8217) specifies the requirements for fuels for use in marine diesel engines and boilers.

How can ship operators and owners to plan ahead for the 0.50% sulphur 2020 limit?

To assist ship operators and owners to plan ahead for the 0.50% sulphur 2020 limit, the MEPC has approved various guidance and guidelines.

The 2019 Guidelines on consistent implementation of 0.50% sulphur limit under MARPOL Annex VI adopted by resolution MEPC.320(74) are available here.

These comprehensive guidelines include a template for a «Fuel Oil Non-Availability Report (FONAR)» set out in Appendix 1 and a «Technical review of identified possible potential safety implications associated with the use of 2020 compliant fuels» set out in appendix 2. (These Guidelines are a non-official version issued in May 2019 and subject to final editorial modifications. But this version is accurate enough in substance for implementation of IMO 2020 sulphur limit. The official version will be issued as part of the final report of MEPC 74 in Summer 2019 at which point the non-official version will be revoked.)

The ship implementation planning guidance includes sections on:

— risk assessment and mitigation plan (impact of new fuels);

— fuel oil system modifications and tank cleaning (if needed);

— fuel oil capacity and segregation capability;

— procurement of compliant fuel;

— fuel oil changeover plan (conventional residual fuel oils to 0.50% sulphur compliant fuel oil); and

documentation and reporting.

Is a FONAR a waiver?

The 2019 Guidelines on consistent implementation of 0.50% sulphur limit under MARPOL Annex VI adopted by resolution MEPC.320(74) here clearly states (in APPENDIX 1):

«3.1 A fuel oil non-availability report is not an exemption. According to regulation 18.2 of MARPOL Annex VI, it is the responsibility of the Party of the destination port, through its competent authority, to scrutinize the information provided and take action, as appropriate.»

«3.2 In the case of insufficiently supported and/or repeated claims of non-availability, the Party may require additional documentation and substantiation of fuel oil non-availability claims. The ship/operator may also be subject to more extensive inspections or examinations while in port.»

«3.3 Ships/operators are expected to take into account logistical conditions and/or terminal/port policies when planning bunkering, including but not limited to having to change berth or anchor within a port or terminal in order to obtain compliant fuel.»

«3.4 Ships/operators are expected to prepare as far as reasonably practicable to be able to operate on compliant fuel oils. This could include, but is not limited to, fuel oils with different viscosity and different sulphur content not exceeding regulatory requirements (requiring different lube oils) as well as requiring heating and/or other treatment on board.»

Small molecules like those in propane, naphtha, gasoline for cars, and jet fuel have relatively low boiling points, and they are removed at the start of the fractional distillation process. Heavier petroleum products like diesel and lubricating oil are much less volatile and distill out more slowly, while bunker oil is literally the bottom of the barrel; the only things more dense than bunker fuel are carbon black feedstock and bituminous residue which is used for paving roads (asphalt) and sealing roofs.

Could the 0.50% limit be delayed?

No. There can be no change in the 1 January 2020 implementation date, as it is too late now to amend the date and for any revised date to enter into force before 1 January 2020.

Will new fuels be needed to meet the 2020 limit? Will there be enough?

It is likely that new blends of fuel oil for ships will be developed, For example, a gas oil, with a very low sulphur content can be blended with heavy fuel oil to lower its sulphur content.

These new blends are likely to cost more initially than the “heavy fuel oil” bunkers (fuel) used by the majority of ships today. Ships can also choose to switch to a different fuel altogether. Or they may continue to purchase heavy fuel oil, but install ”scrubbers” to reduce the output of SOx in order to have an equivalent means to meet the requirement.

Of course, some ships are already using low sulphur fuel oil to meet the even more stringent limits of 0.10% m/m when trading in the already-established emission control areas. So those fuel oil blends suitable for ECAS, will also meet the 0.50% m/m limit in 2020. However, there is a cost differential, and these blends are more expensive than heavy fuel oil.

A study commissioned by IMO into the «Assessment of fuel oil availability» concluded that the refinery sector has the capability to supply sufficient quantities of marine fuels with a sulphur content of 0.50% m/m or less and with a sulphur content of 0.10% m/m or less to meet demand for these products, while also meeting demand for non-marine fuels.

Consistent compliance with the new limit is vital. What is IMO doing about that?

Monitoring, compliance and enforcement of the new limit falls to Governments and national authorities of Member States that are Parties to MARPOL Annex VI. Flag States (the State of registry of a ship) and port States have rights and responsibilities to enforce compliance.

IMO is working with Member States as well as industry (including the shipping industry and the bunker supply and refining industry) to identify and mitigate transitional issues so that ships may meet the new requirement.

For example, developing guidance, developing standardised formats for reporting fuel oil non availability if a ship cannot obtain compliant fuel oil and considering verification and control issues.

The MEPC also approved guidance on ship implementation planning, part of a set of guidelines being developed by IMO for consistent implementation of the MARPOL regulation coming into effect from 1 January 2020.

The MEPC also approved Guidance on best practice for fuel oil suppliers. The Guidance is intended to assist fuel oil purchasers and users in assuring the quality of fuel oil delivered to and used on board ships, with respect to both compliance with the MARPOL requirements and the safe and efficient operation of the ship. The guidance pertains to aspects of the fuel oil purchase up to the loading of the purchased fuel oil on board.

Do small ships have to comply with the sulphur limit from 2020?

Yes, the MARPOL regulations apply to all ships. Only larger ships of 400 gross tonnage and above engaged in voyages to ports or offshore terminals under the jurisdiction of other Parties have to have an International Air Pollution Prevention Certificate, issued by the ship’s flag State. But all sizes of ships will need to use fuel oil that meets the 0.50% limit from 1 January 2020.

Some smaller ships may already be using fuel oil that meets the limit, such as a marine distillate suitable for their engines. (Small ships operating in the already-designated emission control areas will be using fuel oil that meets the 0.10% limit in those emission control areas.)

Does the sulphur limit apply only to ships on international voyages?

The sulphur oxides regulation (MARPOL Annex VI, regulation 14) applies to all ships, whether they are on international voyages, between two or more countries; or domestic voyages, solely within the waters of a Party to the MARPOL Annex.

The major greenhouse gases are water vapour, which causes about 36–70% of the greenhouse effect; carbon dioxide (CO2), which causes 9–26%; methane (CH4), which causes 4–9%; nitrous oxide (N2O) that accounts for about 5.6 percent of greenhouse gas emissions from human activities and ozone (O3), which causes 3–7%.

The greenhouse effect is the process by which absorption and emission of infrared radiation by gases in a planet’s atmosphere, warm its lower atmosphere and surface, to include warming the oceans and melting the ice caps.

Internal Controls for SOX Compliance: A Practical Guide

What are SOX Internal Controls?

The 2002 Sarbanes Oxley Act (SOX) is a federal law that aims to increase the reliability of financial reporting, and protect investors from corporate fraud. It covers publicly traded companies operating in the United States, and also some private companies, as defined in SOX sections 302 and 404.

Section 404 of the SOX regulation requires organizations to implement internal controls, to ensure their financial reporting is accurate. SOX controls, also known as SOX 404 controls, are rules that can prevent and detect errors in a company’s financial reporting process. Internal controls are used to prevent or discover problems in organizational processes, ensuring the organization achieves its goals.

SOX controls must be applied and verified in all cycles leading to the company’s financial report or financial results. Internal auditors must conduct regular compliance audits to verify that appropriate controls are in place and that they are functioning properly.

The SOX standard does not provide a list of specific controls. Instead, it requires organizations to define their own controls to meet the regulator’s goals. These could include, for example, access control, change management, segregation of duties, cybersecurity solutions, and backup systems.

SOX Compliance Requirements

To better understand the context of internal controls within the SOX standard, here is a brief review of SOX requirements:

Senior management responsibility

In publicly-traded companies, the CEO and CFO are directly responsible for any financial report filed with the Securities Exchange Commission (SEC). Since the CEO and CFO are held responsible, they face severe criminal penalties for violations, including prison time and millions of dollars in fines.

Internal control report

SOX requires organizations to file a report which demonstrates that the management of the company remains responsible for the internal control structure applied to financial records.

To ensure transparency, all material weaknesses must be immediately reported to senior management. Sections 302 and 404 are highly relevant to this aspect of the act:

Data security policies

SOX requires organizations to create and maintain a data security policy that protects the storage and use of all financial information. SOX requires organizations to consistently implement this policy and clearly communicate it to all employees.

Proof of compliance

SOX requires organizations to create and maintain compliance documentation, which must be provided to auditors upon request. Additionally, organizations are required to continually perform SOX control testing, as well as monitor and measure SOX compliance objectives.

SOX Internal Controls Audits: 4 Key Areas of Focus

An enterprise’s internal audit and controls testing is generally the largest, most complex and time-consuming part of an SOX compliance audit. This is because internal controls include all of the company’s IT assets, including computers, hardware, software, and all other electronic devices that have access to financial data.

A SOX IT controls audit focuses on the following areas:

1. Access Control

Evaluating how the organization restricts access and implements access control measures, to ensure only the right people can physically and electronically access sensitive financial information. This includes physical access measures like locks and video surveillance for server rooms, and digital measures like authentication and credentials management using an identity and access management (IAM) solution.

2. IT Security

Evaluating how the organization identifies sensitive data, protects it against cyberattacks, monitors who is accessing it and how, and detects security incidents. In the event of an accident, the company must be able to take corrective action in a timely and effective manner. This requires dedicated security staff, effective security procedures, and security tools such as a Security Information and Event Management (SIEM) system.

3. Data Backup

Evaluating how the organization backs up data and key systems to minimize business disruption and data loss in case of a disaster. Both the original systems, and the data center containing backups or standby systems that store financial data, must be compliant with SOX requirements.

4. Change Management

Evaluating how the organization manages changes to the IT environment, such as new employees, new computing infrastructure, new software, updates to existing software, and configuration changes. Changes must be recorded and any sensitive changes should be monitored, anomalies should be reported and acted on to prevent security breaches.

SOX Controls Best Practices

The following best practices can help you more effective implement and audit SOX controls.

Use a Top Down Risk Assessment Approach

According to the PCAOB, it is best to use a top down approach to assess risks related to SOX controls. Start from financial statements, identify entities related to each statement, and define the controls needed for the important accounts and disclosures related to the statement.

The end goal of a risk assessment is to identify possible risks, existing controls, and whether they are enough to satisfy SOX requirements. If not, the next step is to develop new procedures to implement the missing controls.

Related content: learn more in our guide to internal control weaknesses (coming soon)

Determining Materiality in SOX

It is critical to determine materiality, to understand the level of controls required for a financial statement to comply with SOX. The following guidelines can help you determine materiality:

Limit the Number of SOX Controls By Identifying Key Controls

It can be tempting to apply a control every time a risk is identified in the risk assessment process. However, this leads to a large number of controls, which can be difficult to implement and enforce and may needlessly impact business operations.

It is advised to limit the number of controls to the minimum necessary, by identifying key controls. A simple way to differentiate key vs. non-key controls is to ask the question: “what risk does this control mitigate, and is the risk low or high?” If the risk is low, the control may not be needed. Use this approach to prioritize your efforts.

Identify Manual vs. Automated Controls

In a large enterprise, it is infeasible to implement all controls manually. Differentiate between:

The first two categories fall under the responsibility of the SOX audit team. However, the third category is taken care of by existing ITGC efforts. By identifying this third category, and focusing your efforts on the first two, you can save a significant amount of time in SOX control auditing.

Automating SOX Internal Controls Auditing with Pathlock

Preparing for a SOX audit can be a stressful, expensive, and time consuming process, but it doesn’t have to be. Pathlock provides an automated, real-time solution to proving compliance with your internal controls for SOX. Continuous controls monitoring can ensure that you are always tracking your compliance, so there are no major surprises when the audit season comes around.

In today’s modern enterprise, nearly 100% of the financially relevant activity happens in modern applications like SAP, Oracle, Workday, and NetSuite. By connecting directly into your business applications, Pathlock can automatically monitor activity in these applications to surface any violations to controls, and pinpoint and quantify the financial impact of any risks. Internal and external auditors alike trust Pathlock’s reports to prove control enforcement and compliance with regulations.

Financial Impact Prioritization

Pathlock automatically prioritizes your most critical violations by quantifying access risk by tying violations to real dollar amounts of the out-of-policy transactions

Comprehensive Rulebook

Pathlock’s catalog of over 500+ rules, Pathlock can provide out-of-the-box coverage for controls related to SOX, GDPR, CCPA, HIPAA, NIST, and other leading compliance frameworks.

Real-time Access Mitigation

Pathlock allows user to quickly investigate and respond to potential risky transactions by reviewing access, deprovisioning users, forcing 2FA, or even allowing Pathlock to respond intelligently in real-time, terminating suspicious sessions and blocking transactions in real time

Out-of-the-Box Integrations

Pathlock’s out of-the-box integrations extend workflows to the provisioning and service desk tools you already have in place such as ServiceNow, SailPoint, Okta, Azure AD, SAP GRC, and more

Lateral SOD Correlation

All entitlements and roles are correlated across a user’s behavior, consolidating activities and showing cross application SOD’s between financially relevant applications

Continuous Control Monitoring

Pathlock identifies the largest risks by monitoring 100% of financial transactions from applications like SAP in real-time, surfacing violations for remediation and investigation

Источники информации:

- http://www.digitalrefining.com/article/1000722/best-practices-for-sox-emissions-control

- http://www.maritime-executive.com/article/imo-answers-questions-on-the-2020-sox-regulation

- http://change-climate.com/GreenHouse_Gases/Sulphur_Dioxide_Sulfur_Oxides_SO2_SOx.htm

- http://pathlock.com/learn/internal-controls-for-sox-compliance-a-practical-guide/