How can a process of welding be defined

How can a process of welding be defined

I. Text A: «Welding», Text В: «Other types of welding»

II. Famous People of Science and Technology: James Prescott Joule.

Text A: «WELDING»

Welding is a process when metal parts arejoined together by the application of heat, pressure, or a combination of both. The processes of welding can be divided into two main groups:

• pressure welding, when the weld isachieved by pressure and

• heat welding, when the weld is achieved by heat. Heat welding is the most common welding process used today.

Nowadays welding is usedinstead of bolting andriveting in the construction of many types of structures, including bridges, buildings, and ships. It is also abasicprocess in themanufacture of machinery and in the motor and aircraft industries. It is necessary almost in all productions where metals are used.

The welding processdepends greatly on the properties of the metals, thepurpose of their application and theavailable equipment. Welding processes are classified according to thesources of heat and pressure used.

The welding processes widely employed today include gas welding, arc welding, and resistancewelding. Other joining processes arelaser welding, andelectron-beam welding.

Gas Welding

Gas welding is a non-pressure process using heat from a gasflame. The flame is applied directly to the metal edges to be joined andsimultaneously to a filler metalin the form ofwire or rod, called the welding rod, which ismelted to thejoint.Gas welding has theadvantage of using equipment that is portable and does notrequire an electric power source. Thesurfaces to be welded and the welding rod arecoated withflux, afusible material that shields the material from air, which would result in a defective weld.

Arc Welding

Arc-welding is the most important welding process for joining steels. It requires a continuous supply of either direct or alternating electrical current. This current is used tocreate an electric arc, which generates enough heat to melt metal and create a weld.

Arc welding has several advantages over other welding methods. Arc welding is faster because the concentration of heat is high. Also, fluxes are not necessary in certain methods of arc welding. The most widely used arc-welding processes areshielded metal arc, gas-tungsten arc, gas-metal arc, andsubmerged arc.

Shielded Metal Arc

In shielded metal-arc welding, a metallic electrode, which conducts electricity, is coated with flux and connected to a source of electric current. The metal to be welded is connected to the other end of the same source of current. An electric arc is formed bytouching thetipof the electrode to the metal and then drawing it away. The intense heat of the arc melts both parts to be welded and the point of the metal electrode, which suppliesfillermetal for the weld. This process is used mainly for welding steels.

Vocabulary:

to join — соединять

pressure welding — сварка давлением

heat welding — сварка нагреванием

instead — вместо, взамен

bolting — скрепление болтами

riveting — клепка

basic — основной

to manufacture — изготовлять

to depend — зависеть от

purpose — цель

available — имеющийся в наличии

equipment — оборудование

source — источник

gas welding — газосварка

arc welding — электродуговая сварка

resistance welding — контактная сварка

laser welding — лазерная сварка

electron-beam welding — электронно-лучевая сварка

flame — пламя

edge— край

simultaneously — одновременно

filler — наполнитель

wire — проволока

rod — прут, стержень

to melt — плавить(ся)

joint — соединение, стык

advantage — преимущество

to require — требовать нуждаться

surface— поверхность

coated — покрытый

flux — флюс

fusible — плавкий

to shield — заслонять, защищать

touching — касание

tip — кончик

General understanding:

1. How can a process of welding be defined?

2. What are the two main groups of processes of welding?

3. How can we join metal parts together?

4. What is welding used for nowadays?

5. Where is welding necessary?

6. What do the welding processes of today include?

7. What are the principles of gas welding?

8. What kinds of welding can be used for joining steels?

9. What does arc welding require? 10. What is the difference between the arc welding and shielded-metal welding?

Exercise 6.1. Find the following words and word combinations in the text:

I. Text A: «Welding», Text В: «Other types of welding»

II. Famous People of Science and Technology: James Prescott Joule.

Text A: «WELDING»

Welding is a process when metal parts arejoined together by the application of heat, pressure, or a combination of both. The processes of welding can be divided into two main groups:

• pressure welding, when the weld isachieved by pressure and

• heat welding, when the weld is achieved by heat. Heat welding is the most common welding process used today.

Nowadays welding is usedinstead of bolting andriveting in the construction of many types of structures, including bridges, buildings, and ships. It is also abasicprocess in themanufacture of machinery and in the motor and aircraft industries. It is necessary almost in all productions where metals are used.

The welding processdepends greatly on the properties of the metals, thepurpose of their application and theavailable equipment. Welding processes are classified according to thesources of heat and pressure used.

The welding processes widely employed today include gas welding, arc welding, and resistancewelding. Other joining processes arelaser welding, andelectron-beam welding.

Gas Welding

Gas welding is a non-pressure process using heat from a gasflame. The flame is applied directly to the metal edges to be joined andsimultaneously to a filler metalin the form ofwire or rod, called the welding rod, which ismelted to thejoint.Gas welding has theadvantage of using equipment that is portable and does notrequire an electric power source. Thesurfaces to be welded and the welding rod arecoated withflux, afusible material that shields the material from air, which would result in a defective weld.

Arc Welding

Arc-welding is the most important welding process for joining steels. It requires a continuous supply of either direct or alternating electrical current. This current is used tocreate an electric arc, which generates enough heat to melt metal and create a weld.

Arc welding has several advantages over other welding methods. Arc welding is faster because the concentration of heat is high. Also, fluxes are not necessary in certain methods of arc welding. The most widely used arc-welding processes areshielded metal arc, gas-tungsten arc, gas-metal arc, andsubmerged arc.

Shielded Metal Arc

In shielded metal-arc welding, a metallic electrode, which conducts electricity, is coated with flux and connected to a source of electric current. The metal to be welded is connected to the other end of the same source of current. An electric arc is formed bytouching thetipof the electrode to the metal and then drawing it away. The intense heat of the arc melts both parts to be welded and the point of the metal electrode, which suppliesfillermetal for the weld. This process is used mainly for welding steels.

Vocabulary:

to join — соединять

pressure welding — сварка давлением

heat welding — сварка нагреванием

instead — вместо, взамен

bolting — скрепление болтами

riveting — клепка

basic — основной

to manufacture — изготовлять

to depend — зависеть от

purpose — цель

available — имеющийся в наличии

equipment — оборудование

source — источник

gas welding — газосварка

arc welding — электродуговая сварка

resistance welding — контактная сварка

laser welding — лазерная сварка

electron-beam welding — электронно-лучевая сварка

flame — пламя

edge— край

simultaneously — одновременно

filler — наполнитель

wire — проволока

rod — прут, стержень

to melt — плавить(ся)

joint — соединение, стык

advantage — преимущество

to require — требовать нуждаться

surface— поверхность

coated — покрытый

flux — флюс

fusible — плавкий

to shield — заслонять, защищать

touching — касание

tip — кончик

General understanding:

1. How can a process of welding be defined?

2. What are the two main groups of processes of welding?

3. How can we join metal parts together?

4. What is welding used for nowadays?

5. Where is welding necessary?

6. What do the welding processes of today include?

7. What are the principles of gas welding?

8. What kinds of welding can be used for joining steels?

9. What does arc welding require? 10. What is the difference between the arc welding and shielded-metal welding?

Exercise 6.1. Find the following words and word combinations in the text:

1. сварка давлением

2. тепловая сварка

3. болтовое (клепаное) соединение

4. процесс сварки

5. зависеть от свойств металлов

6. имеющееся оборудование

7. сварочный электрод

8. плавкий материал

9. дефектный сварной шов

10. непрерывная подача электрического тока

11. электрическая дуга

12. источник электрического тока

Поперечные профили набережных и береговой полосы: На городских территориях берегоукрепление проектируют с учетом технических и экономических требований, но особое значение придают эстетическим.

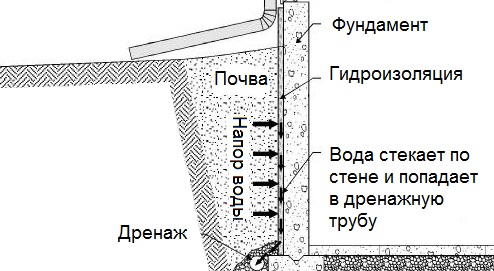

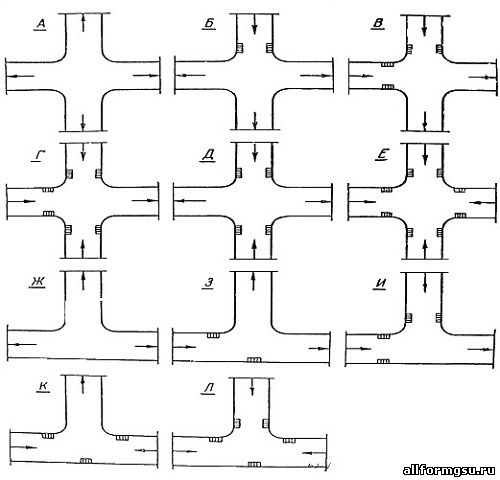

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого.

Организация стока поверхностных вод: Наибольшее количество влаги на земном шаре испаряется с поверхности морей и океанов (88‰).

Answer the questions.

КОГПОБУ

«Вятский автомобильно-промышленный коледж»

МЕТОДИЧЕСКОЕ ПОСОБИЕ

ПО АНГЛИЙСКОМУ ЯЗЫКУ

по профессии:

«Сварщик»

Welding.

Read and translate the text.

Welding is a process when metal parts are joined together by the application of heat, pressure, or a combination of both. The processes of welding can be divided into two main groups:

•pressure welding, when the weld is achieved by pressure and

•heat welding, when the weld is achieved by heat. Heat welding is the most common welding process used today.

Nowadays welding is used instead of bolting and riveting in the construction of many types of structures, including bridges, buildings, and ships. It is also a basic process in the manufacture of machinery and in the motor and aircraft industries. It is necessary almost in all productions where metals are used.

The welding process depends greatly on the properties of the metals, the purpose of their application and the available equipment. Welding processes are classified according to the sources of heat and pressure used: gas welding, arc welding, and resistance welding. Other joining processes are laser welding, and electron-beam welding.

Vocabulary

Answer the questions.

1. How can a process of welding be defined?

2. What are the two main groups of processes of welding?

3. How can we join metal parts together?

4. What is welding used for nowadays?

5. Where is welding necessary?

6. What do the welding processes of today include?

Find in the text.

1. Сегодня сварка используется вместо соединения болтами.

2. Сварочный процесс в основном зависит от свойств металла.

3. Она необходима почти во всех производствах, где используется металл.

4. Сварка нагреванием – самый распространенный процесс сварки сегодня.

5. Это основной процесс в машиностроении.

Find 8 words and write them.

| H | E | A | T | Q | J | Z | P |

| D | F | G | G | H | O | C | A |

| X | C | V | T | G | I | F | R |

| W | E | L | D | I | N | G | T |

| V | B | A | N | N | M | A | R |

| A | W | S | E | S | X | S | F |

| R | S | E | S | C | E | H | V |

| C | X | R | M | E | T | A | L |

Read in the text.

1. …… are laser welding, and electron-beam welding.

2. …… in all productions where metals are used.

3. …… on the properties of the metals.

4. …… or a combination of both.

5. …… when the weld is achieved by heat.

Text 2

Kinds of welding.

Read and translate the texts.

Gas Welding.

Gas welding is a non-pressure process using heat from a gas flame. The flame is applied directly to the metal edges to be joined and simultaneously to a filler metal in the form of wire or rod, called the welding rod, which is melted to the joint. Gas welding has the advantage of using equipment that is portable and does not require an electric power source. The surfaces to be welded and the welding rod are coated with flux, a fusible material that shields the material from air, which would result in a defective weld.

Arc Welding

Arc-welding is the most important welding process for joining steels. It requires a continuous supply of either direct or alternating electrical current. This current is used to create an electric arc, which generates enough heat to melt metal and create a weld.

Arc welding has several advantages over other welding methods. Arc welding is faster because the concentration of heat is high. Also, fluxes are not necessary in certain methods of arc welding. The most widely used arc-welding processes are shielded metal arc, gas-tungsten arc, gas- metal arc, and submerged arc.

Vocabulary

flame пламя edge край

simultaneously одновременно filler наполнитель

wire проволока rod прут, стержень

to melt плавить(ся) joint соединение, стык

Answer the questions.

1. What do the welding processes of today include?

2. What are the principles of gas welding?

3. What kinds of welding can be used for joining steels?

Помоги срочно с упражнением по английскому

Welding is a process when metal parts are joined together by the application of heat, pressure, or a combination of both. The processes of welding can be divided into two main groups:

•pressure welding, when the weld is achieved by pressure and

•heat welding, when the weld is achieved by heat. Heat welding is the most common welding process used today.

Nowadays welding is used instead of bolting and

riveting in the construction of many types of structures, including bridges, buildings, and ships. It is also a basic process in the manufacture of machinery and in the motor and aircraft industries. It is necessary almost in all productions where metals are used.

The welding process depends greatly on the properties of the metals, the purpose of their application and the available equipment. Welding processes are classified according to the sources of heat and pressure used: gas welding, arc welding, and resistance welding. Other joining processes are laser welding, and electron-beam welding.

Gas Welding

Gas welding is a non-pressure process using heat from a gas flame. The flame is applied directly to the metal edges to be joined and simultaneously to a filler metal in the form of wire or rod, called the welding rod, which is melted to the joint. Gas welding has the advantage of using equipment that is portable and does not require an electric power source. The surfaces to be welded and the welding rod are coated with flux, a fusible material that shields the material from air, which would result in a defective weld.

Arc Welding

Arc-welding is the most important welding process for joining steels. It requires a continuous supply of either direct or alternating electrical current. This current is used to create an electric arc, which generates enough heat to melt metal and create a weld.

Arc welding has several advantages over other welding methods. Arc welding is faster because the concentration of heat is high. Also, fluxes are not necessary in certain methods of arc welding. The most widely used arc-welding processes are shielded metal arc, gas-tungsten arc, gas- metal arc, and submerged arc.

Resistance Welding

In resistance welding, heat is obtained from the resistance of metal to the flow of an electric current. Electrodes are clamped on each side of the parts to be welded, the parts are subjected to great pressure, and a heavy current is applied for a short period of time. The point where the two metals touch creates resistance to the flow of current. This resistance causes heat, which melts the metals and creates the weld. Resistance welding is widely employed in many fields of sheet metal or wire manufacturing and is often used for welds made by automatic or semi-automatic [«semi «Ltq’mxtlk] machines especially in automobile industry.

Вопросы

Answer the questions:

1.How can a process of welding be defined?

2. What are the two main groups of processes of welding?

3.How can we join metal parts together?

4. What is welding used for nowadays?

5. Where is welding necessary?

6.What do the welding processes of today include?

7. What are the principles of gas welding?

8. What kinds of welding can be used for joining steels?

9.What does arc welding require?

10. What is the difference between the arc welding and shielded-metal welding?

What Is Welding?- Definition | Types of Welding

What is Welding?

Welding is a fabrication process that uses heat, pressure, or both to fuse two or more parts together, forming a joint as the parts cool. Welding is typically used on metals and thermoplastics, but can also be used on wood. The completed welded joint can be referred to as a weldment.

Some materials require the use of specific processes and techniques. Some are considered “unweldable,” a term not typically found in dictionaries but useful and descriptive in engineering.

The parts that are joined are known as base material. The material that is added to form the joint is called a filler or consumable. Because of the shape of these materials, they can be referred to as a base plate or tube, flux-cored wire, consumable electrode (for arc welding), etc.

Consumables are usually chosen to be similar in composition to the base material, thus forming a homogenous weld, but there are occasions, such as when welding brittle cast irons, when a filler with a very different composition and, therefore, properties are used. These welds are called heterogeneous.

The completed welded joint may be referred to as a weldment.

Definition of welding

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure, or both forming a join as the parts cool. Welding is usually used on metals and thermoplastics but can also be used on wood. The completed welded joint may be referred to as a weldment.

How Does Welding Work?

Welding works by joining two materials together without a separate binder material. Unlike brazing and soldering, which use a binder that has a lower melting point, welding joins the two workpieces directly together.

Most welding done today falls into one of two categories: arc welding and torch welding.

Arc welding uses an electrical arc to melt the work materials as well as a filler material (sometimes called the welding rod) for welding joints. Arc welding involves attaching a grounding wire to the welding material or other metal surface.

Another wire known as an electrode lead is placed on the material to be welded. Once that lead is pulled away from the material, an electric arc is generated. It’s a little like the sparks you see when pulling jumper cables off a car battery. The arc then melts the workpieces along with the filler material that helps to join the pieces.

Feeding the filler into the welding joint takes steady hands and an eye for detail. As the rod melts, the welder must continuously feed the filler into the joint using small, steady, back-and-forth motions. These motions are what give welds their distinctive appearance. Going too fast or slow, or holding the arc too close or far away from the material can create poor welds.

Shielded metal arc welding (SMAW or stick welding), gas metal arc welding (more commonly known as a metal inert gas, or MIG welding), and gas tungsten arc welding (frequently called tungsten inert gas, or TIG, welding) all exemplify arc welding.

These three common methods each offer unique advantages and drawbacks. Stick welding, for instance, is inexpensive and easy to learn. It’s also slower and less versatile than some other methods. Oppositely, TIG welding is difficult to learn and requires an elaborate welding rig. TIG welding produces high-quality welds, however, and can weld materials that other methods can’t.

Torch welding represents another popular welding method. This process typically uses an oxyacetylene torch to melt the working material and welding rod. The welder controls the torch and rod simultaneously, giving him or her a lot of control over the weld. While torch welding has become less common industrially, it’s still frequently used for maintenance and repair work, as well as in sculptures.

Types of Welding

1. MIG WELDING Or GMAW

MIG welding is one of the most common types of welding that beginners need to learn. MIG welding is used in the auto industry to repair vehicle exhaust and also in the construction of houses and buildings. This is a type of arc welding that uses a continuous wire called an electrode. You also use a shielding gas that flows through the welding gun and protects against contamination.

MIG welding is actually two different types of welding. The first use bare wire and the second uses flux core. Bare wire MIG welding can be used to join thin pieces of metal together. Flux core MIG welding can be used outdoors as it does not require a flow meter or gas supply. MIG welding is usually the welding of choice for DIY and amateur welders who don’t have the cash to spend on expensive equipment.

2. TIG WELDING Or GTAW

Like MIG, TIG welding also uses the arc, but it is also one of the more difficult welding techniques to learn. TIG welding uses a tungsten electrode. Tungsten is one of the hardest metal materials. It does not dissolve or burn off.

Tig welding can be done by a process known as fusion, which may or may not use a filler metal. TIG also uses an external gas supply such as argon or helium.

Two hands are required for TIG welding. One hand guides the rod while the other holds a TIG torch. This torch produces the heat and arc used to weld most common metals including aluminum, steel, nickel alloys, copper alloys, cobalt, and titanium.

TIG welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze, and even gold. TIG is a useful welding process for bike frames, lawnmowers, door handles, fenders, and more.

The aerospace and automotive industries use TIG welding as do other industrial markets. This is also a great type of welding for Iowa as it can be very useful for farmers to weld wagon frames, fenders, and other vital equipment.

3. STICK WELDING Or SMAW

Want to take your welding to go? A major benefit of stick welding is that it is portable. Stick welding is used in construction, maintenance and repair, underwater pipelines, and industrial manufacturing. For this type of welding, use shielded metal arc welding, better known as stick welding.

Stick welding, also known as arc welding, does it the old-fashioned way. Stick welding is a bit more difficult to master than MIG welding, but you can buy stick welding equipment for very little money if you want to try it at home. Stick welding uses a stick electrode welding rod.

They use a consumable and protected electrode or stick. The stick softens and bonds metals by heating with an electric arc between a covered metal electrode and the base metal workpiece. As the stick melts, its protective cover also melts, shielding the welding area from oxygen and other gases that may be in the air.

4. FLUX-CORED ARC WELDING (FCAW)

This type of welding is similar to MIG welding. In fact, MIG welders can often double duty as FCAW welders as well. Just like MIG welding, a wire that serves as the electrode and filler metal is passed through your rod. This is where things start to differ. For FCAW, the wire has a flux core that forms a gas shield around the weld. This eliminates the need for an external gas supply.

FCAW is better suited for thicker, heavier metals as it is a high-temperature type of weld. Because of this, it is often used for repairs on heavy equipment. It’s an efficient process that doesn’t generate a lot of waste. Since no external gas is required, it is also cost-effective. There will be some slag left over, however, and it needs a bit of cleaning up to make a nicely finished weld.

5. PLASMA ARC WELDING

Plasma arc welding is a precision technique and is commonly used in aerospace applications where the metal thickness is 0.015 inches. An example of such an application would be an engine blade or air seal. Plasma arc welding is technically very similar to TIG welding, but the electrode is recessed and the ionizing gases in the arc are used to generate heat.

The usual gas combination is argon as the plasma gas, with argon plus 2 to 5% hydrogen as the shielding gas. Helium can be used for a plasma gas, but as it is hotter this reduces the amperage of the nozzle.

6. LASER BEAM WELDING

This type of welding can be used on metals or thermoplastics. As the name suggests, a laser is used as a heat source to create the welds. It can be used on carbon steels, stainless steels, HSLA steels, titanium, and aluminum. It can be easily automated with robotics and is therefore widely used in manufacturing, for example in the automotive industry.

7. ELECTRON-BEAM WELDING

This is a type of welding in which a high-speed electron beam uses kinetic energy to generate heat and weld two materials together. This is a very demanding form of welding that is carried out mechanically, mostly in a vacuum.

8. GAS WELDING

Gas welding is only rarely used and has been largely superseded by TIG welding. Gas welders require oxygen and acetylene and are very portable. They are still sometimes used to weld parts of car exhaust back together.

9. ATOMIC HYDROGEN WELDING

Atomic hydrogen welding is a form of extremely high heat welding formerly known as Atomic Arc Welding. In this type of welding, two tungsten electrodes are shielded with hydrogen gas. It can reach temperatures in excess of that of an acetylene torch and can be conducted with or without filler metal. This is an older form of welding that has been replaced by MIG welding in recent years.

10. ELECTROSLAG

This is an advanced welding process used to join the thin edge of two metal plates together vertically. Instead of the weld being made on the outside of a joint, it takes place between the edges of the two panels.

A copper electrode wire is passed through a consumable metal guide tube that serves as the filler metal. When current is applied, the arc is created and a weld begins at the bottom of the seam and is slowly moved up, creating the weld instead of the seam as it progresses. This is an automated process and is done by machine.

Types Of Welds

1. Fillet Welds

Fillet welding refers to the process of joining two pieces of metal together when they are perpendicular or at an angle. These welds are commonly referred to as tee joints, which are two pieces of metal perpendicular to each other, or lap joints, which are two pieces of metal that overlap and are welded at the edges.

The weld is triangular in shape and may have a concave, flat, or convex surface depending on the welder’s technique. Welders use fillet welds when connecting flanges to pipes and welding cross-sections of infrastructure, and when bolts are not strong enough and will wear off easily.

2. Groove Welds

A groove weld is defined as an opening between the two joint members which provides the space to contain the metal. Groove welds are the most used welds after the fillet weld. The second most popular type of weld is the groove weld.

The groove weld refers to beads that are deposited in a groove between two members to be joined. The type of weld used will determine the manner in which the seam, joint, or surface is prepared.

Compared with other forms of welding, the groove welding process is generally more time-consuming, harder to perform, and typically requires special beveling on one or both surfaces being joined.

3. Surfacing Weld

These are welds composed of one or more strings or weave beads deposited on an unbroken surface to obtain desired properties or dimensions.

Surfacing is a welding process used to apply a hard, wear-resistant layer of metal to surfaces or edges of worn-out parts. It is one of the most economical methods of conserving and extending the life of machines, tools, and construction equipment.

A surfacing weld is composed of one or more stringer or weave beads. Surfacing, sometimes known as hard facing or wear facing, is often used to build up worn shafts, gears, or cutting edges.

Surfacing welds are commonly used to add a wear-resistant layer of metal to an object to strengthen its surface or rebuild worn areas. In these cases, a metal with a greater wear resistance than the base metal is used to perform the welding.

This technique is one of the most cost-effective methods for protecting and prolonging the life of equipment and tools used in aggressive, high-wear applications. Surface welding can also be used in conjunction with square butt joints to enhance the quality of the final weld.

4. Plug Weld

A Plug Weld, also known as the Rosette Weld, is when two metals are fused through welds placed in small circular holes. This process is typically done on two overlapping metals, with the top metal having the holes for the weld to be deposited.

Plug welding is an alternative to spot welding used by vehicle manufacturers where there is insufficient access for a spot welder. For DIY car restoration, it’s generally used instead of spot welding on panel flanges that would have originally been spot welded.

Plug welds when done properly tend to be stronger than the original spot welds. Rally car builders often use the technique, and it is acceptable in a UK MOT test as an alternative to spot welds were repairing older cars

Other applications include:

5. Slot Weld

A slot weld joins the surface of a piece of material to another piece through an elongated hole. The hole can be open at one end and can be partially or completely filled with weld material.

This is a weld made in an elongated hole in one member of a lap or tee joint joining that member to the surface of the other member that is exposed through the hole. This hole may be open at one end and may be partially or completely filled with weld metal.

With slot welds, one surface is joined to another through an elongated hole. The difference between plug and slot welds is that the plug weld’s shape is characterized by its diameter, whereas the slot weld’s shape is characterized by both diameter and length.

Depending on the part’s specifications, one end of the hole may be open, or the hole can be partially or completely filled with weld material.

6. Flash Weld

Flash welding is a method of resistance welding that eliminates the need for filler metals. During the flash welding process, a current is applied to create a resistance between the two surfaces to be joined. When the two surfaces come together at small contact points, the current flows and melt the material.

The melted material then exits the joint in a spray of molten particles, which creates a distinctive flashing action. Oxides and other contaminants are eliminated from the interface while a heat-softened zone is formed at the ends of the two surfaces.

When enough material has melted, a force is then applied to join the surfaces. This facilitates the creation of a butt weld with no residual melted material in the joint.

7. Seam Weld

Seam welding is the process of joining two similar or dissimilar materials at the seam by the use of electric current and pressure. Seam welding is possible thanks to the contact resistance created between the two metals. As current passes between the metals, heat gets generated at the small gap.

The process is mostly used on metals since they conduct electricity easily and can sustain relatively high pressures. As current passes between the metals, heat gets generated at the small gap. Electrodes maintain and control the flow of electricity.

8. Spot Weld

Spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together by applying pressure and heat from an electric current to the weld area.

It works by contacting copper alloy electrodes to the sheet surfaces, whereby pressure and electric current are applied and heat is generated by the passage of current through resistive materials such as low carbon steel.

9. Upset Weld

Upset welding (UW)/resistance butt welding is a welding technique that produces coalescence simultaneously over the entire area of abutting surfaces or progressively along a joint, by the heat obtained from resistance to electric current through the area where those surfaces are in contact.

Pressure is applied before heating is started and is maintained throughout the heating period. The equipment used for upset welding is very similar to that used for flash welding. It can be used only if the parts to be welded are equal in cross-sectional area.

The abutting surfaces must be very carefully prepared to provide for proper heating. The difference from flash welding is that the parts are clamped in the welding machine and force is applied bringing them tightly together.

High-amperage current is then passed through the joint, which heats the abutting surfaces. When they have been heated to a suitable forging temperature an upsetting force is applied and the current is stopped. The high temperature of the work at the abutting surfaces plus the high pressure causes coalescence to take place. After cooling, the force is released and the weld is completed.

Advantages Of Welding

Disadvantage of welding

Application Of Welding

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is usually used on metals and thermoplastics but can also be used on wood. The completed welded joint may be referred to as a weldment.

Welding works by joining two materials together without a separate binder material. Unlike brazing and soldering, which use a binder that has a lower melting point, welding joins the two workpieces directly together.

There are four main types of welding. MIG – Gas Metal Arc Welding (GMAW), TIG – Gas Tungsten Arc Welding (GTAW), Stick – Shielded Metal Arc Welding (SMAW) and Flux-cored – Flux-cored Arc Welding (FCAW).

Basic types of welding:

1. MIG Welding – Gas Metal Arc Welding (GMAW)

2. TIG Welding – Gas Tungsten Arc Welding (GTAW)

3. Stick Welding – Shielded Metal Arc Welding (SMAW)

4. Flux Welding – Cored Arc Welding (FCAW)

5. Energy Beam Welding (EBW)

6. Atomic Hydrogen Welding (AHW)

7. Gas Tungsten-Arc Welding.

8. Plasma Arc Welding.